Gas 2-Plate Crepe Maker

Category: Crepe Maker

-

+86-13929587046 WhatsApp

-

dfwuch67@gmail.com Email

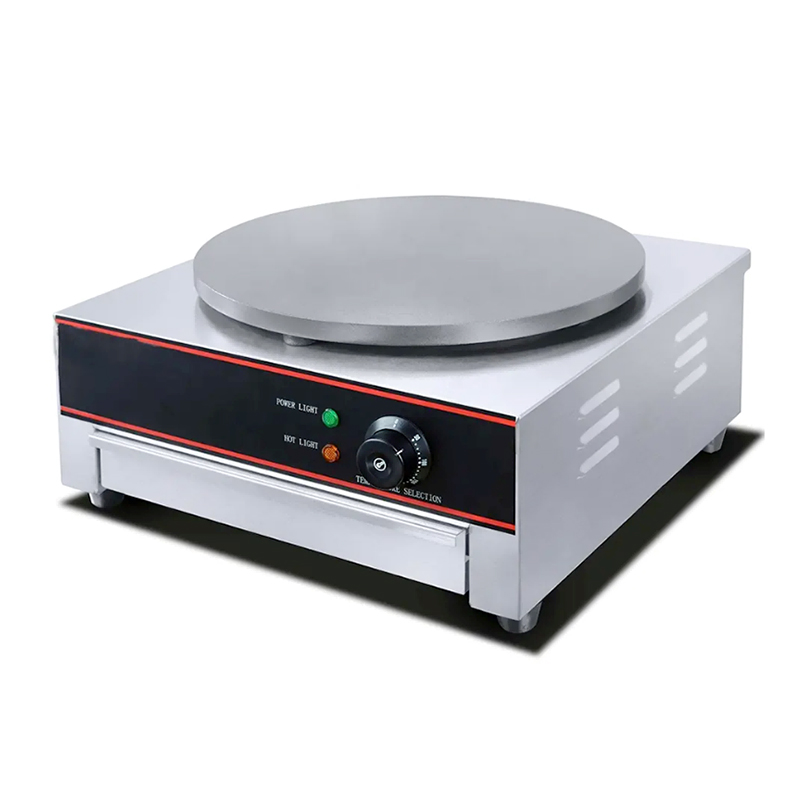

Large Electric Crepe Maker is a double-plate gas-fired crepe machine designed for mid-to-high-end commercial catering scenarios. The whole machine is made of all stainless steel, with a metal brushed surface treatment, and has a size of 860×490×235mm. It is equipped with two independent heating discs with a diameter of 40cm. The material is cast iron + food-grade Teflon coating. There are two gas inlets and independent gas valve knobs at the bottom. Each heating disc is equipped with an independent burner. There are ventilation and heat dissipation holes on both sides of the equipment. Four non-slip rubber feet firmly fix the equipment. It is suitable for centralized food delivery in catering kitchens, and can also be deployed in mobile stalls or on-site stalls.

Gas 2-Plate Crepe Maker Parameter

| Model | MLP-2R |

| Name | Gas 2-Plate Crepe Maker |

| Burner | 2 Burners |

| Pwoer | Gas LPG/2800Pa |

| Dimension | 860*490*235mm |

| Packing Size | 940*640*300mm |

| Baking Tray Diameter | 40cm |

| Usage | Food Industry Equipment |

| Feature | High Efficiency |

| Warranty | 1 Year |

| N.W/G.W | 22kg/25kg |

Gas 2-Plate Crepe Maker Features

1. Independent control of two ovens, precise firepower matching diverse needs

Large Electric Crepe Maker is equipped with two independent combustion systems and gas valve control components, which support the adjustment of the heating intensity of the left and right baking trays. It uses standard LPG liquefied gas fuel, the gas pressure is set to 2800Pa, the firepower responds quickly, the heating time is short, and it only takes 2-3 minutes to enter the working state. The burner flame can be adjusted freely to achieve flexible switching between "low temperature slow baking" and "high temperature fast cooking", meeting the differences in crepe craftsmanship of sweet, salty, different thicknesses and ingredients. The double oven design supports single operation and simultaneous duplex mode. It can save energy and reduce consumption by closing one side during off-peak periods, and run at full speed during peak periods to ensure meal delivery efficiency. It is an ideal equipment architecture for commercial and efficient production.

2. Teflon-coated thickened baking tray, non-stick and easy to clean, safer to use

The two heating trays of Large Electric Crepe Maker with a diameter of 40cm and a thickness of 2cm are made of high-density cast iron, with excellent heat storage and thermal conductivity, which can maintain uniform heat distribution for a long time and avoid the problem of cold edges and hot in the middle. The surface of the baking tray is coated with food-grade Teflon non-stick coating, which can withstand high temperatures, corrosion resistance, non-toxic and environmentally friendly. It not only prevents the ingredients from sticking to the tray and breaking, but also significantly reduces the difficulty of cleaning. It can be cleaned with just a damp cloth, saving a lot of labor maintenance costs. Even in high-frequency use scenarios, the coating has good durability and is not easy to peel off, further ensuring food safety and equipment stability.

3. Anti-slip rubber foot pad design to enhance operational safety and body stability

The bottom of the Large Electric Crepe Maker is equipped with four highly elastic and heat-resistant rubber foot pads, which have excellent grip and shock absorption and buffering performance. Its main function is to maintain the stability of the equipment on the table or operating platform, prevent the equipment from sliding or tipping due to force during operation, and ensure the personal safety of the user. At the same time, the rubber material has good heat insulation properties, which can effectively block the high temperature conduction from the heating plate and the bottom of the furnace, and protect the surface of the operating table from being baked or deformed. In addition, the rubber foot pad can also absorb vibration noise during work, improve operating comfort, and is particularly suitable for long-term continuous operation in a crowded business environment.

1. Applied to the boutique French dessert shop "Delifrance Pastry Studio" in Penang, Malaysia

In the well-known French dessert brand "Delifrance Pastry Studio" in Penang, Large Electric Crepe Maker is widely used in the open kitchen area to provide high-speed crepe production support for the store's breakfast and afternoon tea services. The brand attaches great importance to the efficiency of equipment delivery and the consistency of finished products. Through the independent fire control function, sweet and savory crepes can be made separately to meet the personalized taste needs of different customers. The owner pointed out: "Compared with traditional single-oven equipment, the double-plate dual-control system saves us at least 40% of waiting time, and also makes the overall quality of crepes more stable and uniform."

2. Applied to the mobile stalls of the fast food chain brand "CREP STATION" in Santiago, Chile

"CREP STATION" is a local fast food chain brand in Latin America, which has a large number of mobile stalls and street outdoor points in Santiago, Chile. Because the equipment needs to be moved frequently, connected to gas and started quickly, Large Electric Crepe Maker has become one of the brand's main equipment. The compact structure and dual-burner design of the machine body enable it to be quickly deployed and ignited in any venue. The independent gas control knob makes it easy for novice employees to get started without complicated training. The head of brand equipment management said: "The Large Electric Crepe Makeris the most cost-effective of all the equipment we have evaluated. It can meet the needs of continuous production throughout the day and is easy to maintain."

3. Applied to the kitchen of the "KARIM CAFÉ" commercial catering complex in Cairo, Egypt

Located in the center of Cairo, "KARIM CAFÉ" is a large commercial catering complex integrating coffee, light meals and French desserts. The kitchen area of the store uses MLP-2R as the main machine for crepe making, mainly serving the daily peak traffic during lunch and evening. Considering the convenient local gas supply and high electricity costs, the Large Electric Crepe Maker is an ideal choice. The kitchen chef said: "We use it for the task of producing about 500 crepes every day, and there has never been any performance instability. In particular, the thickness and temperature control ability of the baking tray are particularly outstanding during peak hours."

DINGFENG POPULAR PRODUCTS

Jiangmen Dingfeng Saving Kitchen Electric Co., Ltd. owns a modern production factory covering an area of over 10,000 square meters. Inside the factory, more than 80 well - trained employees perform their respective duties, forming a professional and efficient production team. Since its establishment, with exquisite technology and innovative ideas, the company has successfully produced more than 1000 different types of products. The rich variety of products fully demonstrates our strong production capacity and innovative vitality.

The company's main business is extensive, covering various kitchen electrical products. The product range is rich and diverse, including desktop luxury stoves cooker range, griddle, waffle baker, barbecue grills, deep fryers, panini grills, ice cream machine etc., fast food equipment, snack equipment, refrigeration, and other general commercial kitchen equipment. We have cooperated with more than 200 well-known brands around the world and have won a good reputation in the international market with our high-quality products and services, becoming a trusted partner for many customers. Our brand MARUPIN is widely well known by customers domestic and overseas.

Our company has invested heavily in introducing advanced equipment, equipped with world-class CNC punching, cutting, bending, and welding series processing equipment, and has strong technical strength to adapt to product development, technical correction, and product transformation. Every product needs to go through several strict quality inspection processes to ensure that the product has the best appearance and performance, delivering the most cost-effective product to every user and providing reliable product guarantee for customers.