Electric 1-Plate Crepe Maker

Category: Crepe Maker

-

+86-13929587046 WhatsApp

-

dfwuch67@gmail.com Email

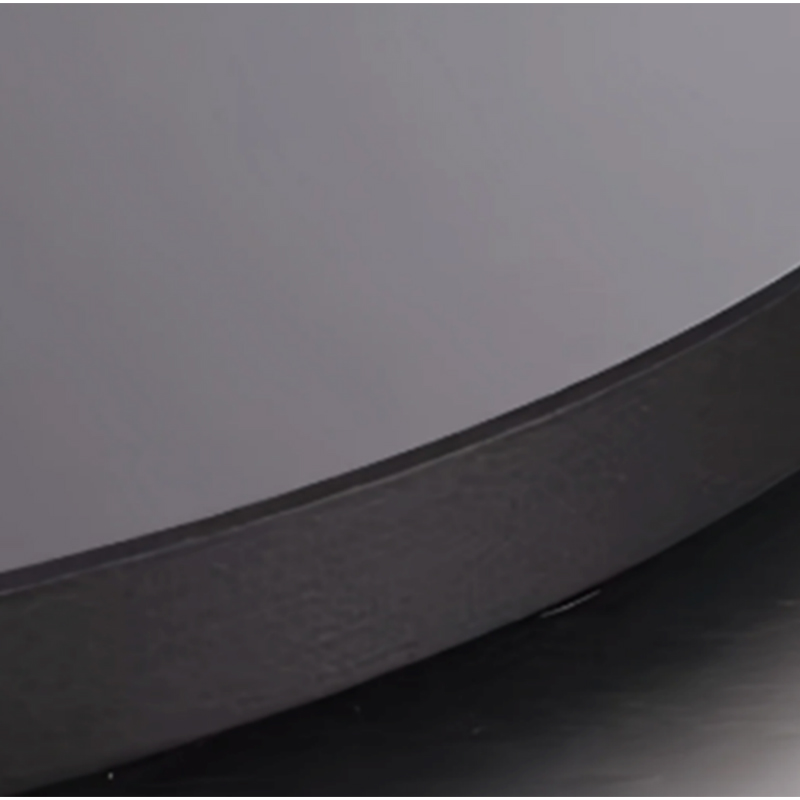

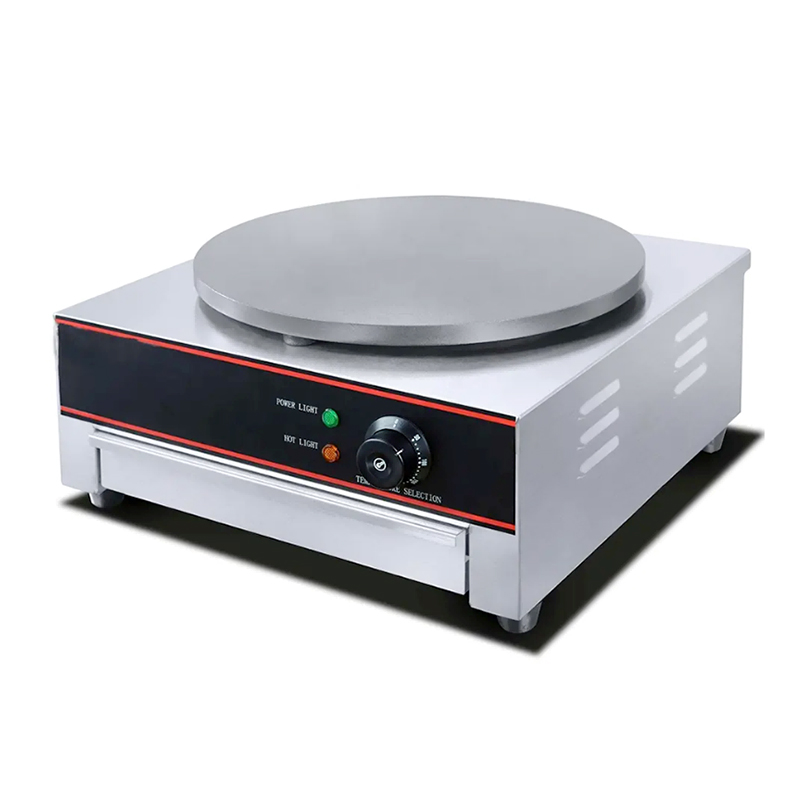

The professional electric crepe machine adopts a round stainless steel design, the cooking area adopts a 2 cm thick iron heating plate, the surface is coated with food-grade Teflon non-stick coating, and the bottom is equipped with four thickened non-slip rubber pads. This is an electric crepe machine designed for commercial kitchens and efficient catering places.

Electric 1-Plate Crepe Maker Parameter

| Model | MLP-1 |

| Name | Electric 1-Plate Crepe Maker |

| Voltage/Frentcy | 220~240V/50~60Hz |

| Pwoer | 3KW |

| Dimension | 490*450*230mm |

| Packing Size | 570*505*250mm |

| Baking Tray Diameter | 40cm |

| Usage | Food Industry Equipment |

| Feature | Easy Operation |

| Warranty | 1 Year |

| N.W/G.W | 13.6kg/15kg |

Electric 1-Plate Crepe Maker Features

Sturdy and durable

The cooking panel of the professional electric crepe machine adopts a 2 cm thick iron heating plate. Compared with the traditional thin plate structure, it has stronger heating capacity and heat dissipation performance. It can still maintain stable heating efficiency during continuous high-temperature use in commercial kitchens, greatly reducing the risk of uneven baking and partial burning of food. This structure is particularly suitable for making a large number of crepes, pancakes, egg rolls and other products, ensuring the stability and beautiful color of the products, which is the main guarantee for heating of professional catering equipment.

Non-stick coating

The surface of the heating plate is coated with food-grade Teflon non-stick coating, which has excellent anti-stick effect. Even in oil-free or low-oil operation, the crepe can be removed smoothly to avoid the accumulation of food residues and difficulty in cleaning. In addition, the professional electric crepe machine is resistant to high temperatures, up to 260°C or more, and has excellent stability in high-frequency cooking environments, extending the service life of the machine and improving kitchen work efficiency.

High stability

The bottom of the professional electric crepe machine is equipped with thickened rubber feet, which can greatly improve the stability of the equipment on the operating table and prevent it from slipping due to frequent operation or environmental vibration. In addition, the rubber material also plays a role in buffering and shockproofing, effectively reducing the fatigue load of the internal components of the equipment due to long-term work, thereby extending the service life of the whole machine. At the same time, the foot pad design is conducive to rapid heat dissipation at the bottom of the equipment and improving the overall heat dissipation efficiency.

Accurate temperature control

The professional electric crepe machine is equipped with a mechanical temperature control system with a switch. Users can freely set the temperature range between 50°C and 300°C according to the different needs of the ingredients being made. The button scale is clear and the feedback feels smooth. Even in a fast-paced operating environment, the firepower can be accurately controlled to avoid product problems caused by overheating or insufficient firepower. The temperature control system of the professional electric crepe machine can adapt to different menu requirements and is suitable for processing various ingredients, such as sweets, proteins, etc.

Dessert chain stores

In dessert chain brands such as J.CO Donuts and Auntie Anne's, professional electric crepe machines are widely used to produce standardized crepes in large quantities every day. Its precise temperature control and non-stick effect ensure that each crepe crust has uniform thickness and attractive color, which not only increases production speed, but also helps to improve customer satisfaction and repurchase rate, especially suitable for continuous order operation during peak hours.

Shopping mall food experience

Professional electric crepe machines are widely distributed in food centers in shopping malls such as Westfield and SM Malls. Due to the simple and elegant shape and intuitive operation process of professional electric crepe machines, many merchants choose open kitchens to display the production process, attract customers to stop and create an interactive atmosphere on the spot. Its fast heating and non-stick coating can be matched with various fillings to show the baking effect and effectively improve the on-site sales conversion rate.

Breakfast restaurant in star-rated hotels

In the buffet restaurants of star-rated hotels such as Marriott and Hilton, professional electric crepe machines are one of the important equipment of open hot food stations. It can continuously make sweet and savory crepes, omelets, French pancakes, etc. to meet the different needs of customers.

DINGFENG POPULAR PRODUCTS

Jiangmen Dingfeng Saving Kitchen Electric Co., Ltd. owns a modern production factory covering an area of over 10,000 square meters. Inside the factory, more than 80 well - trained employees perform their respective duties, forming a professional and efficient production team. Since its establishment, with exquisite technology and innovative ideas, the company has successfully produced more than 1000 different types of products. The rich variety of products fully demonstrates our strong production capacity and innovative vitality.

The company's main business is extensive, covering various kitchen electrical products. The product range is rich and diverse, including desktop luxury stoves cooker range, griddle, waffle baker, barbecue grills, deep fryers, panini grills, ice cream machine etc., fast food equipment, snack equipment, refrigeration, and other general commercial kitchen equipment. We have cooperated with more than 200 well-known brands around the world and have won a good reputation in the international market with our high-quality products and services, becoming a trusted partner for many customers. Our brand MARUPIN is widely well known by customers domestic and overseas.

Our company has invested heavily in introducing advanced equipment, equipped with world-class CNC punching, cutting, bending, and welding series processing equipment, and has strong technical strength to adapt to product development, technical correction, and product transformation. Every product needs to go through several strict quality inspection processes to ensure that the product has the best appearance and performance, delivering the most cost-effective product to every user and providing reliable product guarantee for customers.