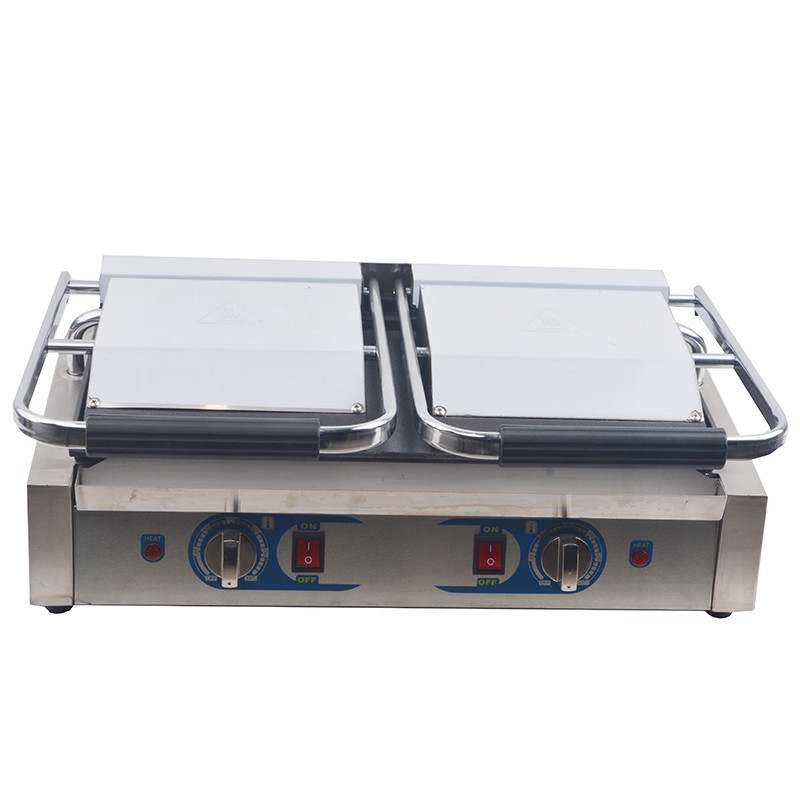

Electric Double Contact Flat+Grooved Grill

Category: Electric Contact Grill

-

+86-13929587046 WhatsApp

-

dfwuch67@gmail.com Email

Double Electric Contact Grills adopts upper and lower special-shaped heating panel design: the upper plate is two independent grooved cast iron plates, and the lower plate is a whole flat cast iron plate, with Teflon non-stick coating on the surface. The size of the whole machine is 565×370×190mm, equipped with two independent temperature control knobs and working indicator lights, the left and right heating zones can be operated independently, and there are efficient heat dissipation holes on both sides of the machine body, and two heat-resistant and scald-proof handles on the front. It is a double-head electric heating contact concave flat combination oven designed for diversified catering products, with excellent functional flexibility and space utilization efficiency.

Electric Double Contact Flat+Grooved Grill Parameter

| Model | MLP-813KA |

| Name | Electric Double Contact Flat+Grooved Grill |

| Voltage/Frentcy | 220~240V/50~60Hz |

| Pwoer | 3.6KW |

| Dimension | 565*370*190mm |

| Packing Size | 630*435*260mm |

| Usage | Food Industry Equipment |

| Feature | High Productivity |

| Warranty | 1 Year |

| N.W/G.W | 22kg/25kg |

Electric Double Contact Flat+Grooved Grill Features

1. Double control and dual zone design

The two upper pressing plates of Double Electric Contact Grills are equipped with independent power switches and temperature control knobs, which can adjust the temperature separately according to different product requirements, so as to achieve dual use of one machine: such as heating cooked meat slices on one side and pressing raw toast on the other side, without interfering with each other, and flexibly responding to busy stalls and complex menus. The power input is 220240V/5060Hz, with a total power of up to 3.6KW, which can support continuous operation during peak hours.

2. Grooved + flat plate type

The upper plate of Double Electric Contact Grills adopts a grooved cast iron plate design, which can form professional-grade burn marks on the surface of ingredients such as chicken steak, hamburgers, and grilled sausages, improving the appearance of the product; the lower plate is a flat and unpatterned panel to ensure that the bottom is evenly heated, easy to shape, and no burn marks remain. It is suitable for baked products that require a smooth appearance, such as scones and burritos, to achieve one machine with multiple categories of production, and the menu can be quickly switched without changing the equipment.

3. Teflon non-stick coating

The upper and lower panels are covered with high-quality Teflon non-stick coating, which is not only highly anti-sticky and easy to fall off, but also can be baked without oil or very little oil, significantly reducing kitchen fumes, improving environmental cleanliness and food health level. In addition, the Double Electric Contact Grills coating is wear-resistant and heat-resistant, not easy to fall off, simple to maintain, and saves more than 40% of cleaning time compared with traditional cast iron plates.

4. Structural safety guarantee

Double Electric Contact Grills are equipped with high-strength anti-scalding handles, and the outer layer is covered with heat-insulating materials to prevent high temperature from burning the hands. The fixed support system can firmly support the upper plate when there is no pressure, avoiding accidental pressure on food or operators. The bottom of Double Electric Contact Grills is also equipped with non-slip rubber pads, which can keep the equipment stable and not shake even when used on oily or slippery countertops, ensuring the safety of people and machines during long-term work.

1. "ALSHAYA EXPRESS" Airport Chain Fast Food Station in Dubai, UAE

Double Electric Contact Grills are widely deployed in multiple catering stalls at Dubai International Airport under ALSHAYA EXPRESS. As the core equipment of its fast breakfast supply system, they are specially used to make healthy and low-oil foods such as whole wheat sandwiches and French omelettes. The special-shaped design of the upper and lower plates of Double Electric Contact Grills can simultaneously present beautiful charred marks and a complete bottom, meeting the dual needs of international passengers for vision and taste. According to feedback from the brand, Double Electric Contact Grills supports all-day operation without performance degradation.

2. The central kitchen of the French Paris dessert baking chain "MonDélice"

The central kitchen of "MonDélice" chooses Double Electric Contact Grills for the baking and forming process of multi-layer pancakes. The upper and lower special-shaped baking surfaces of the equipment can make indentations on the top layer to beautify the product shape while ensuring the neat and shaped crust. The brand R&D director said: "The temperature control stability and operational flexibility of Double Electric Contact Grills are very suitable for the pastry process and play a key role in the texture presentation of our products."

3. The cooking course training hall of "Gourmet Food School" in Johannesburg, South Africa

Gourmet Food School uses Double Electric Contact Grills as the standard training equipment for its advanced class courses. Students use Double Electric Contact Grills to practice pressing ingredients and temperature control experiments, such as: concave pressing chicken steak, flat hot pressing toast, etc. The instructor said: "Double Electric Contact Grills has a rigorous structure, heavy material, and commercial-grade operating feel. It is a very rare cost-effective equipment in cooking teaching."

4. "Healthy BENTO" takeaway kitchen production line in Hong Kong, China

In the Healthy BENTO takeaway factory, Double Electric Contact Grills are arranged in the central hot food processing line for low-oil pressing and molding of tofu, vegetarian chicken, and dried tofu. The grooved upper press plate can quickly produce baking patterns, improving the visual expression of the product; while the flat bottom plate ensures that the original shape of the ingredients is not damaged, greatly improving the standardized production efficiency. Its dual-control operation mode is suitable for multi-station flow operations and has now become a regular equipment for the pre-processing of the brand's best-selling products.

5. "TOASTINA CAFÉ" Internet celebrity handmade toast store in Jakarta, Indonesia

"TOASTINA CAFÉ" is famous for its customized thick-cut toast, and Double Electric Contact Grills are used for on-site open-shelf display-style pressing and baking operations. The concave upper plate can create a unique visual texture for the top of the toast, attracting customers to take photos and check in; the lower plane provides complete baking support, ensuring that the toast is crispy on the outside and soft on the inside, with stable product quality, thereby improving the brand's social communication efficiency and customer stickiness.

DINGFENG POPULAR PRODUCTS

Jiangmen Dingfeng Saving Kitchen Electric Co., Ltd. owns a modern production factory covering an area of over 10,000 square meters. Inside the factory, more than 80 well - trained employees perform their respective duties, forming a professional and efficient production team. Since its establishment, with exquisite technology and innovative ideas, the company has successfully produced more than 1000 different types of products. The rich variety of products fully demonstrates our strong production capacity and innovative vitality.

The company's main business is extensive, covering various kitchen electrical products. The product range is rich and diverse, including desktop luxury stoves cooker range, griddle, waffle baker, barbecue grills, deep fryers, panini grills, ice cream machine etc., fast food equipment, snack equipment, refrigeration, and other general commercial kitchen equipment. We have cooperated with more than 200 well-known brands around the world and have won a good reputation in the international market with our high-quality products and services, becoming a trusted partner for many customers. Our brand MARUPIN is widely well known by customers domestic and overseas.

Our company has invested heavily in introducing advanced equipment, equipped with world-class CNC punching, cutting, bending, and welding series processing equipment, and has strong technical strength to adapt to product development, technical correction, and product transformation. Every product needs to go through several strict quality inspection processes to ensure that the product has the best appearance and performance, delivering the most cost-effective product to every user and providing reliable product guarantee for customers.