Electric Single Contact Full Grooved Grill

Category: Electric Contact Grill

-

+86-13929587046 WhatsApp

-

dfwuch67@gmail.com Email

Commercial Electric Contact Grills uses 304 stainless steel shell, thickened cast iron heating plate, Teflon coating on the upper and lower plates, and upper and lower groove heating plates. The upper plate is 23×23cm and the lower plate is 21.5×21.5cm. The top is equipped with a humanized anti-scalding handle and a heat-resistant shaft suspension system. The bottom is equipped with a stainless steel oil collection tray to facilitate centralized oil collection and simplify the cleaning process. It is also equipped with rubber non-slip foot pads. The overall size is 305×370×190mm and the net weight is only 10kg. It is a desktop electric hot pressing equipment that combines high efficiency and compact structure.

Electric Single Contact Full Grooved Grill Parameter

| Model | MLP-811 |

| Name | Electric Single Contact Full Grooved Grill |

| Voltage/Frentcy | 220~240V/50~60Hz |

| Pwoer | 1.8KW |

| Dimension | 305*370*190mm |

| Packing Size | 435*360*260mm |

| Usage | Food Industry Equipment |

| Feature | Easy Operation |

| Warranty | 1 Year |

| N.W/G.W | 10kg/11.5kg |

Electric Single Contact Full Grooved Grill Features

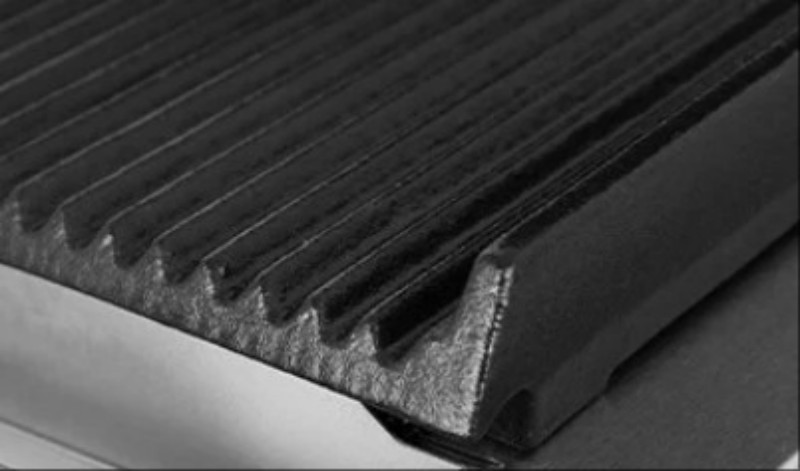

1. Teflon non-stick coating

The upper and lower heating plates of Commercial Electric Contact Grills are made of high-density cast iron, and the surface is covered with food-grade Teflon non-stick coating. While maintaining heat conduction efficiency, it effectively prevents food from sticking. It is particularly suitable for meat, vegetarian food, and toast with low fat content. During high-intensity use, the non-stick property can reduce the scrap rate of ingredients caused by sticking to the pan, and also make the cleaning process of Commercial Electric Contact Grills easier. Just wipe with a damp cloth, which significantly saves labor cleaning time and water costs.

2. Wide temperature control range

Commercial Electric Contact Grills are equipped with a precise temperature adjustment knob and status indicator light system, supporting a temperature control range from 30℃ to 260℃, suitable for the best baking temperature zone for a variety of ingredients. 30100℃ is suitable for slow melting cheese; 150200℃ is suitable for sandwiches and meat fast shaping; 200℃ and above is used for seafood and steak skin charring. Operators can flexibly choose to meet the texture and flavor requirements of different dishes, which is an ideal choice for serving multiple categories of Western meals at the same time.

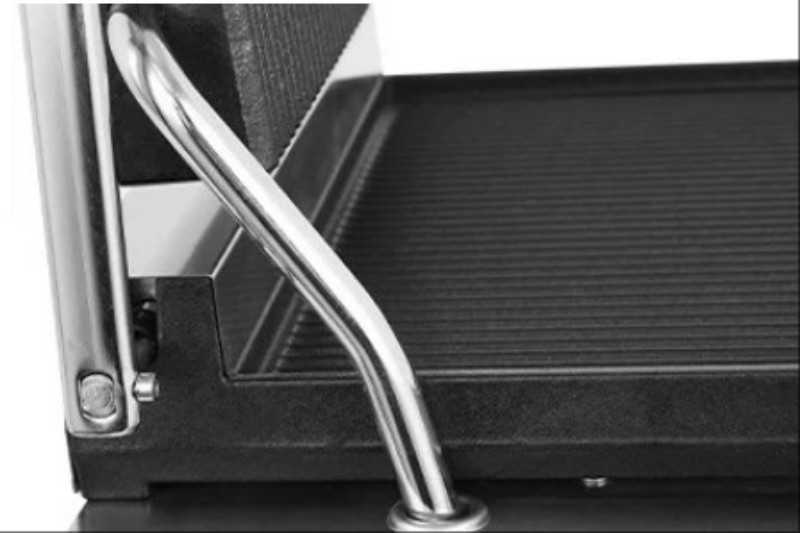

3. Suspended upper cover structure

Commercial Electric Contact Grills adopts a pivot suspension system design, which allows the upper cover to automatically adjust the fitting height according to the thickness of different ingredients when it moves up and down, realizing true contact pressure baking. When it does not need to be completely closed, the upper cover can be kept in a suspended state through a fixed point structure to avoid operating fatigue caused by frequent lifting. This support method is particularly popular in Europe and the United States, where kitchen safety and ergonomics are required, and can reduce the burden on shoulders and arms during long-term operation.

4. Integrated oil collection device

An integrated stainless steel oil tank is provided on the front side of the equipment to receive grease dripping from the upper plate and ingredients. The Commercial Electric Contact Grills oil tank can be easily disassembled and cleaned by pulling out, effectively preventing oil stains from flowing back to the electric heating pipe or control panel area, and extending the life of the internal components of the equipment. For commercial scenarios where frequent food delivery is required, centralized oil collection can also avoid the accumulation of oil stains on the work surface, maintain the hygiene of the operation area, and improve the overall management level of the kitchen.

5. Anti-skid base and insulated handle

The bottom of the Commercial Electric Contact Grills is equipped with four rubber anti-skid pads to form a firm support on the countertop, which can effectively prevent the equipment from sliding even under pressure or under the influence of oil stains on the countertop. The handle is made of engineering plastic anti-scalding material, which can keep the handle temperature suitable when the machine is running at high temperature, greatly reducing the risk of burns when the operator changes ingredients or turns over. It is a design model that takes into account both efficiency and personal safety.

1. Independent boutique sandwich shop in Los Angeles, USA

In Mendocino Farms, a mainstream sandwich specialty brand in Los Angeles, California, Commercial Electric Contact Grills equipment is widely used to make its signature hot-pressed beef sandwiches. Due to strict standards for meat doneness and bread crispness, the upper and lower plate groove heating structure and precise temperature control function of Commercial Electric Contact Grills can provide a stable heating environment to achieve the ideal taste of sandwiches that are crispy on the outside and tender on the inside. In addition, the Teflon non-stick coating can prevent high-sugar sauces from charring and sticking to the plate, saving manual maintenance time.

2. Singapore Changi Airport Food Express Kitchen

Commercial Electric Contact Grills are used in the fast food centralized kitchen system of Singapore Changi Airport to quickly heat and press chicken steaks, chicken rolls and other meals during peak hours. Especially during the peak brunch hours, its upper and lower heating structure and rapid heating function can complete a large number of orders in a short time. Due to its compact size and convenient operation, Commercial Electric Contact Grills are standardized and purchased by local fast food chain brands including Toast Box and Stuff’d for use in takeaway operation points in various terminals.

3. Campus Coffee Shops in London, UK

In many university campuses in the UK, such as King’s College London’s cafes, Commercial Electric Contact Grills are often used by students to make hot meals on demand. For example, cheese and ham sandwiches can be quickly pressed to a ready-to-eat state. The entire machine can be placed on an ordinary countertop and does not rely on a large exhaust system. It is particularly suitable for entrepreneurial student coffee shop operations with limited store space or tight budgets.

4. Nutritional food table at a high-end fitness center in Dubai

In the VIP fitness nutrition table of a high-end fitness brand in Dubai, Commercial Electric Contact Grills are used to quickly process healthy ingredients such as low-fat chicken breast, whole wheat toast and quinoa cakes. Its low-oil non-stick baking and adjustable temperature control can accurately control the fat precipitation and surface carbonization effect during the cooking process. It is an ideal light cooking equipment for fitness people when used with a healthy diet plan.

5. Portable hot food stalls at the Frankfurt open-air market in Germany

In the Frankfurt open-air market, Commercial Electric Contact Grills are used by independent stall owners to press and grill hot dogs, cheese sandwiches and German smoked meat patties on site. Its low-power design is suitable for the temporary power system provided by the market, and the non-stick iron plate can ensure that the food remains neat and tidy in a fast flipping and high temperature environment, satisfying customers' instant consumption visual experience. Some mobile stalls of the German brand Wurstwerk are using Commercial Electric Contact Grills as one of the main grills.

DINGFENG POPULAR PRODUCTS

Jiangmen Dingfeng Saving Kitchen Electric Co., Ltd. owns a modern production factory covering an area of over 10,000 square meters. Inside the factory, more than 80 well - trained employees perform their respective duties, forming a professional and efficient production team. Since its establishment, with exquisite technology and innovative ideas, the company has successfully produced more than 1000 different types of products. The rich variety of products fully demonstrates our strong production capacity and innovative vitality.

The company's main business is extensive, covering various kitchen electrical products. The product range is rich and diverse, including desktop luxury stoves cooker range, griddle, waffle baker, barbecue grills, deep fryers, panini grills, ice cream machine etc., fast food equipment, snack equipment, refrigeration, and other general commercial kitchen equipment. We have cooperated with more than 200 well-known brands around the world and have won a good reputation in the international market with our high-quality products and services, becoming a trusted partner for many customers. Our brand MARUPIN is widely well known by customers domestic and overseas.

Our company has invested heavily in introducing advanced equipment, equipped with world-class CNC punching, cutting, bending, and welding series processing equipment, and has strong technical strength to adapt to product development, technical correction, and product transformation. Every product needs to go through several strict quality inspection processes to ensure that the product has the best appearance and performance, delivering the most cost-effective product to every user and providing reliable product guarantee for customers.