Large Electric Single Contact Full Grooved Grill

Category: Electric Contact Grill

-

+86-13929587046 WhatsApp

-

dfwuch67@gmail.com Email

The most critical heating components of the Electric Contact Grill are the upper and lower large cast iron grill plates. The upper plate measures 340mm x 220mm, and the lower plate measures 345mm x 235mm. Both are fully grooved, combined with Teflon anti-stick coating, and the upper cover supports suspension shaft structure adjustment. The control panel is set on the front of the device. The temperature control range covers 50℃ to 300℃, with high temperature resistant and scald-proof handles and non-slip rubber foot pads. The overall size of the device is 430×370×190mm, weighing 15kg. It is stable and not easy to shift, suitable for use on various operating tables or cooking workstations.

Large Electric Single Contact Full Grooved Grill Parameter

| Model | MLP-811E |

| Name | Large Electric Single Contact Full Grooved Grill |

| Voltage/Frentcy | 220~240V/50~60Hz |

| Pwoer | 2.3KW |

| Dimension | 430*370*190mm |

| Packing Size | 487*427*260mm |

| Usage | Food Industry Equipment |

| Feature | High Productivity |

| Warranty | 1 Year |

| N.W/G.W | 15kg/16.5kg |

Large Electric Single Contact Full Grooved Grill Features

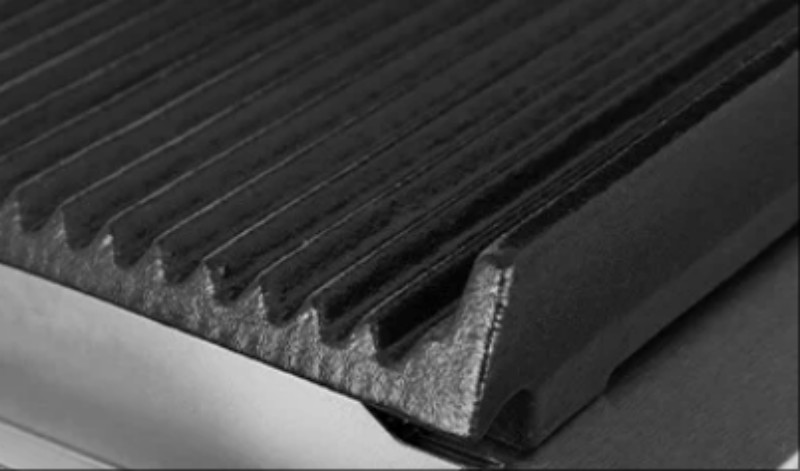

1. Efficient groove plate structure

The upper and lower double-sided full groove grill plate design adopted by the Electric Contact Grill is the core advantage of this device. Unlike traditional flat or hybrid structures, the grooves can not only form a caramel texture on the surface of ingredients such as hamburgers, steaks, and sausages, increasing visual appeal, but also help to discharge excess grease, making the finished product healthier. The upper and lower plates achieve adaptive pressure distribution through the rotating shaft mechanism, and they are close to the ingredients during cooking, without the need for additional manual adjustment and pressing, which effectively improves the efficiency of serving.

2. Food-grade Teflon coating

Both baking plates are treated with food-grade Teflon Teflon coating, which has excellent non-stick properties. Even highly viscous ingredients such as eggs, cheese, and syrup are not easy to adhere. The coating can still remain stable under high temperature conditions, and it is not easy to fall off or change color. It can effectively avoid the accumulation of carbides and improve the kitchen hygiene level. Teflon material has a wide range of heat resistance and can withstand continuous high temperatures of more than 300°C, extending the service life of the baking plate and simplifying the cleaning and maintenance process.

3. Precise temperature control system

Electric Contact Grill is equipped with a professional-grade temperature control knob and working indicator light, allowing users to set the baking temperature according to different food requirements, with a temperature control range of 50°C to 300°C. This wide range of control capability is applicable to the entire process from low-temperature insulation to high-temperature rapid baking, helping restaurants to achieve precise control of different tastes and textures, and improve the stability and standardization of finished products. The knob is covered with insulating material to ensure safe use in long-term working environments.

4. One-piece cast iron plate

The upper and lower heating plates of Electric Contact Grill are made of high-density thick-walled cast iron one-piece molding technology. The thickness of the upper plate is 4.5cm and the thickness of the lower plate is 3.5cm. The plate is strong and pressure-resistant, not easy to deform, and has excellent heat capacity and heat conduction speed. Whether it is continuously pressing multiple sandwiches during peak hours or quickly frying and grilling thick-cut steaks, the cast iron plate can quickly heat up and maintain uniform temperature distribution to ensure consistent baking results and prevent partial scorching or undercooking.

5. Safety and detail design

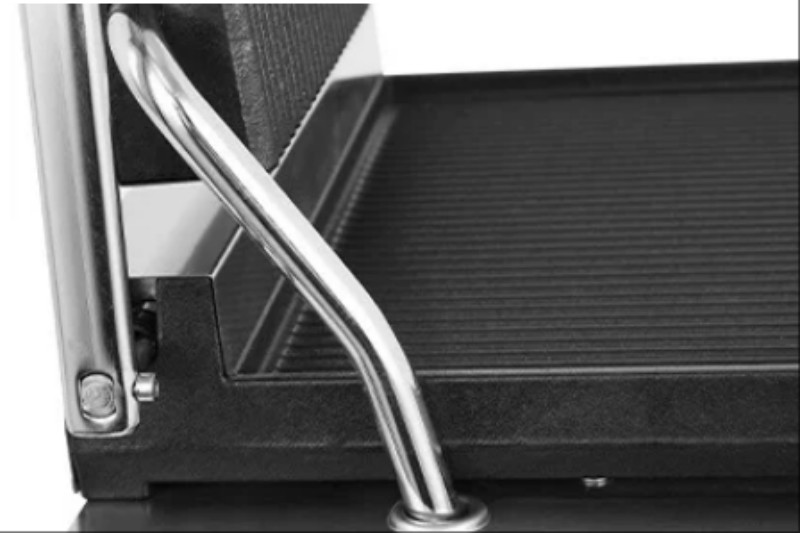

The operating surface is equipped with a high-density stainless steel anti-scalding handle, which is comfortable to hold and can effectively avoid the risk of hand burns. There is a removable 304 stainless steel oil collection tank under the grill to collect excess grease or residue in time to avoid contaminating the internal components of the equipment. Industrial-grade rubber anti-slip pads are set at the four corners of the bottom to ensure that the machine remains stable during operation, even in an environment with a lot of kitchen oil or frequent vibrations. It does not shift, effectively improving the overall safety level of the equipment.

1. Core catering equipment for the Italian light food chain "GustoMio" in Naples, Italy

GustoMio is a light food chain brand covering many cities in southern Italy, with healthy fast food such as Italian panini, grilled vegetable rolls, and whole wheat chicken burgers as its core products. The Electric Contact Grill is used in the hot food processing area of its stores. Due to its grooved embossed structure and rapid heat equalization ability, it can complete a panini baking task within 90 seconds. The brand attaches great importance to the visual appeal of food, and the clear stripes baked by the Electric Contact Grill have become one of its iconic selling points. The equipment is of moderate size and is suitable for high-frequency operation behind the counter, without the need for additional kitchen space.

2. Special oven for portable stalls "HotBite Station" in Dubai Market, UAE

In the famous open-air food court in Dubai, the HotBite Station stall has long used the Electric Contact Grill as the main food delivery equipment for on-site production of beef patties and cheese rolls. The on-site conditions are complex, the space is limited, and the temperature difference is large. The high power output and compact appearance design of the Electric Contact Grill solve the dual needs of portable stalls for efficient food delivery and equipment flexibility. The oven supports fast start and stop, and is suitable for the uninterrupted order mode.

3. Laboratory teaching equipment for baking courses at "École Ferrandi" in Paris, France

As a famous cooking and baking training base in France, Ferrandi Culinary Academy uses Electric Contact Grill to teach embossing techniques in its portable baking experiment course, especially in the production of "embossed sandwiches" and "French sausage rolls", where students can observe the changes in ingredients through temperature adjustment. The technical consultant of the academy praised the Electric Contact Grill for its precise temperature control and safe operation, and it is an ideal model for students to get in touch with commercial baking equipment at the primary level.

4. Factory line usage example of Canadian chain fitness food brand "FuelUp Meals"

FuelUp Meals is a Canadian home delivery brand that focuses on protein meals and fitness foods. In its central kitchen in Toronto, Electric Contact Grill is used to produce protein pancakes and vegetable steaks. Its fast heating and low-oil cooking characteristics help the brand achieve the goal of healthy recipe baking. Thanks to the groove oil drainage design and Teflon non-stick layer, Electric Contact Grill can complete the heating of ingredients without using any oil, which is in line with its "oil-free and healthy" brand proposition.

5. Used in the lunch area of CU, a Korean convenience store

CU is a large Korean convenience store chain. It is equipped with Electric Contact Grill in many stores to press the "Korean Teriyaki Chicken Sandwich" and "Cheese Hot Dog" in the bento series. The size of the equipment is just right to be embedded in the micro kitchen module of the convenience store, which is convenient for non-professionals to operate quickly. Its operation process is simple. You only need to set the temperature and press the lid. The product can be heated and produced within 2 minutes, which greatly improves the standardization of store meals and the turnover rate.

DINGFENG POPULAR PRODUCTS

Jiangmen Dingfeng Saving Kitchen Electric Co., Ltd. owns a modern production factory covering an area of over 10,000 square meters. Inside the factory, more than 80 well - trained employees perform their respective duties, forming a professional and efficient production team. Since its establishment, with exquisite technology and innovative ideas, the company has successfully produced more than 1000 different types of products. The rich variety of products fully demonstrates our strong production capacity and innovative vitality.

The company's main business is extensive, covering various kitchen electrical products. The product range is rich and diverse, including desktop luxury stoves cooker range, griddle, waffle baker, barbecue grills, deep fryers, panini grills, ice cream machine etc., fast food equipment, snack equipment, refrigeration, and other general commercial kitchen equipment. We have cooperated with more than 200 well-known brands around the world and have won a good reputation in the international market with our high-quality products and services, becoming a trusted partner for many customers. Our brand MARUPIN is widely well known by customers domestic and overseas.

Our company has invested heavily in introducing advanced equipment, equipped with world-class CNC punching, cutting, bending, and welding series processing equipment, and has strong technical strength to adapt to product development, technical correction, and product transformation. Every product needs to go through several strict quality inspection processes to ensure that the product has the best appearance and performance, delivering the most cost-effective product to every user and providing reliable product guarantee for customers.