Electric Grill Hot Dogs

Category: Hotdog Grill

-

+86-13929587046 WhatsApp

-

dfwuch67@gmail.com Email

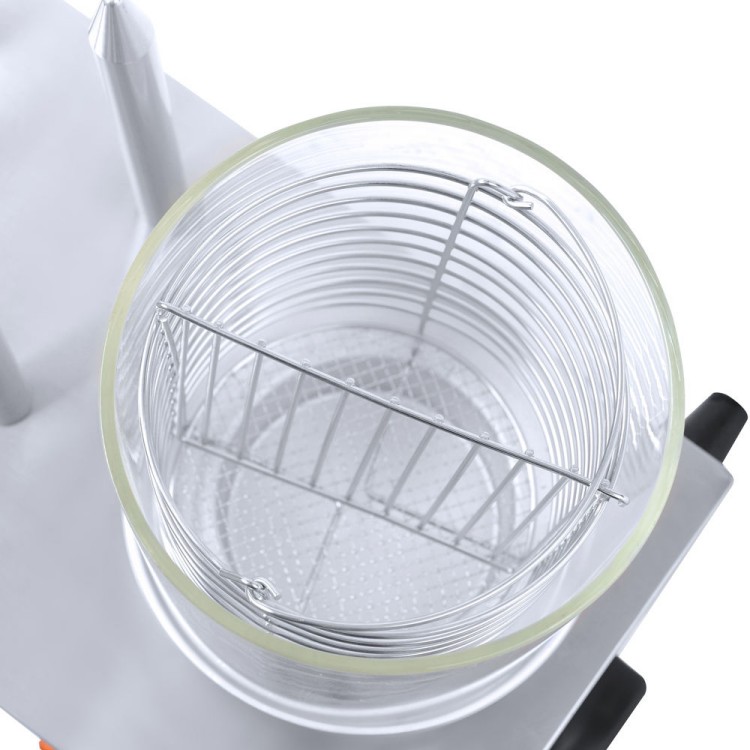

An Instant Beer Glass Froster is a countertop commercial device designed to rapidly cool and condition beverage glasses before serving, creating a consistent chilled surface that enhances drinking comfort and presentation quality. From the user perspective, the experience focuses on immediacy, reliability, and tactile feedback rather than complex operation. The device presents a simple front control interface, allowing operators to activate and regulate the frosting process with minimal steps. When a glass is placed and processed, the resulting surface temperature creates a noticeable cooling sensation that maintains beverage freshness from the first pour to the final sip. The enclosed stainless steel structure and transparent panels provide visual clarity during operation, allowing users to confirm glass positioning and readiness without opening the unit. The overall interaction emphasizes speed, predictability, and cleanliness, ensuring that each glass delivered feels uniform in temperature and handling. This controlled experience is particularly valued where consistency and visual presentation directly affect customer perception and service efficiency.

Electric Grill Hot Dogs Parameter

| Model | MLP-HHD-04 |

| Name | Hot Dog Machine |

| Voltage/Frentcy | 220~240V/50~60Hz |

| Pwoer | 0.6KW |

| Dimension | 480*280*340mm |

| Packing Size | 530*350*450mm |

| Usage | Grilled Hot Dogs |

| Feature | Easy Operation High Efficiency |

| Warranty | 1 Year |

| N.W/G.W | 10kg/13kg |

Electric Grill Hot Dogs Features

Low Power System

The Instant Beer Glass Froster operates with a rated power consumption of 28 watts, allowing continuous use while maintaining low electrical load. At this power level, the unit can remain active for extended service periods without causing circuit strain or excessive energy costs. In quantitative terms, operating the device for ten hours consumes approximately 0.28 kilowatt-hours, which is significantly lower than traditional refrigeration-based cooling equipment. This low wattage design supports stable internal performance without large temperature fluctuations, ensuring repeatable frosting results across multiple cycles. The power configuration also reduces thermal buildup in surrounding equipment zones, which contributes to long-term component stability and predictable daily operation in commercial environments.

Compact Structure

The physical dimensions of the unit measure 196 by 196 by 189 millimeters, forming a near-cubic footprint that minimizes surface occupation. This compact volume allows placement on narrow countertops, back bars, or integrated beverage stations without interfering with adjacent equipment. From a spatial efficiency standpoint, the total occupied area remains under 0.04 square meters, making it suitable for high-density service layouts. The proportional height supports ergonomic access, enabling users to load and retrieve glasses without excessive reach or bending. This structural compactness also simplifies packaging and transport, reducing logistical volume during bulk shipments or equipment redeployment.

Lightweight Build

With a net weight of 5.05 kilograms, the Instant Beer Glass Froster can be repositioned easily by a single operator. This weight threshold falls below common ergonomic handling limits, allowing safe lifting without mechanical assistance. The reduced mass supports flexible station reconfiguration and seasonal layout adjustments. From a stability perspective, the weight distribution remains sufficient to prevent sliding or tipping during operation while still enabling fast relocation when required. The lightweight build also contributes to lower shipping weight classifications, which directly affects freight efficiency in bulk procurement scenarios.

Stainless Housing

The main contact surfaces are constructed from food-grade stainless steel, providing corrosion resistance and hygienic performance under repeated exposure to moisture and temperature changes. Stainless steel surfaces typically maintain structural integrity under temperatures exceeding 100 degrees Celsius, ensuring durability even during prolonged operation. The smooth surface finish reduces residue adhesion, allowing effective cleaning using standard food-service sanitation procedures. Material density and hardness prevent deformation during routine handling, supporting consistent internal alignment and operational stability over time.

Warranty Coverage

The product includes a one-year warranty period, covering manufacturing-related performance issues and component defects. This coverage timeframe aligns with standard commercial equipment lifecycle expectations and provides measurable risk mitigation for procurement decisions. During the warranty period, performance deviations can be addressed without additional capital expenditure, ensuring predictable ownership costs. The defined duration also supports asset planning by allowing operators to align maintenance schedules and replacement cycles with known coverage limits.

Bars

In bar environments, the Instant Beer Glass Froster supports consistent glass conditioning before beverage service. Chilled glass surfaces reduce immediate heat transfer from ambient air, helping maintain beverage temperature stability during serving intervals. This thermal buffering effect improves first-sip experience and reduces foam volatility during pours. The compact form allows integration near tap systems, minimizing operator movement and service time per drink. Operational consistency becomes particularly valuable during peak service periods when throughput and uniform presentation are critical.

Restaurants

Within restaurant beverage stations, the device contributes to standardized drink presentation across multiple service staff. By delivering uniformly chilled glasses, it reduces variability caused by manual cooling methods. Temperature consistency enhances perceived beverage quality and supports repeatable service standards. The enclosed structure also limits external contamination, supporting hygiene protocols required in food-service operations. Placement flexibility allows the unit to fit within existing prep zones without altering workflow layouts.

Catering Services

For catering operations, portability and setup speed are key considerations. The lightweight structure allows transport between venues without specialized handling equipment. Once positioned, the unit can begin operation immediately using standard electrical connections. This rapid deployment supports event-based service environments where temporary setups must deliver professional-grade beverage presentation within limited preparation windows. Consistent output ensures uniform guest experience regardless of venue conditions.

Food Trucks

In mobile food service contexts, space and power availability are constrained. The low 28-watt power requirement enables operation alongside other equipment without overloading onboard electrical systems. The compact footprint fits within narrow prep counters, preserving workspace efficiency. Lightweight construction supports vehicle-mounted configurations and reduces vibration stress during transport. These characteristics collectively support reliable glass preparation in mobile service scenarios.

Event Venues

At event venues, beverage stations often experience fluctuating demand levels. The Instant Beer Glass Froster supports rapid cycling without long recovery times, ensuring readiness during sudden service surges. Visual transparency allows staff to monitor status at a glance, reducing service delays. The consistent output helps maintain brand presentation standards across high-volume events where multiple service points operate simultaneously.

Hotels

Hotel beverage operations prioritize consistency across shifts and staff rotations. The froster provides a standardized glass preparation method that does not rely on individual technique. This consistency supports uniform guest experience across different service times. Compact sizing allows installation behind bars or in service corridors without redesigning existing infrastructure. Low energy consumption aligns with long-term operational efficiency goals.

Beverage Lounges

In lounge environments, visual presentation and tactile experience are central to beverage service. The frosted glass surface enhances sensory perception while maintaining beverage integrity. The controlled preparation process ensures predictable results that align with premium service positioning. Quiet, low-power operation minimizes ambient disturbance, supporting relaxed service atmospheres while maintaining performance reliability.

Electric Grill Hot Dogs More Details about

DINGFENG POPULAR PRODUCTS

Jiangmen Dingfeng Saving Kitchen Electric Co., Ltd. owns a modern production factory covering an area of over 10,000 square meters. Inside the factory, more than 80 well - trained employees perform their respective duties, forming a professional and efficient production team. Since its establishment, with exquisite technology and innovative ideas, the company has successfully produced more than 1000 different types of products. The rich variety of products fully demonstrates our strong production capacity and innovative vitality.

The company's main business is extensive, covering various kitchen electrical products. The product range is rich and diverse, including desktop luxury stoves cooker range, griddle, waffle baker, barbecue grills, deep fryers, panini grills, ice cream machine etc., fast food equipment, snack equipment, refrigeration, and other general commercial kitchen equipment. We have cooperated with more than 200 well-known brands around the world and have won a good reputation in the international market with our high-quality products and services, becoming a trusted partner for many customers. Our brand MARUPIN is widely well known by customers domestic and overseas.

Our company has invested heavily in introducing advanced equipment, equipped with world-class CNC punching, cutting, bending, and welding series processing equipment, and has strong technical strength to adapt to product development, technical correction, and product transformation. Every product needs to go through several strict quality inspection processes to ensure that the product has the best appearance and performance, delivering the most cost-effective product to every user and providing reliable product guarantee for customers.