Commercial Popcorn Popper Machine

Category: Popcorn Machine

-

+86-13929587046 WhatsApp

-

dfwuch67@gmail.com Email

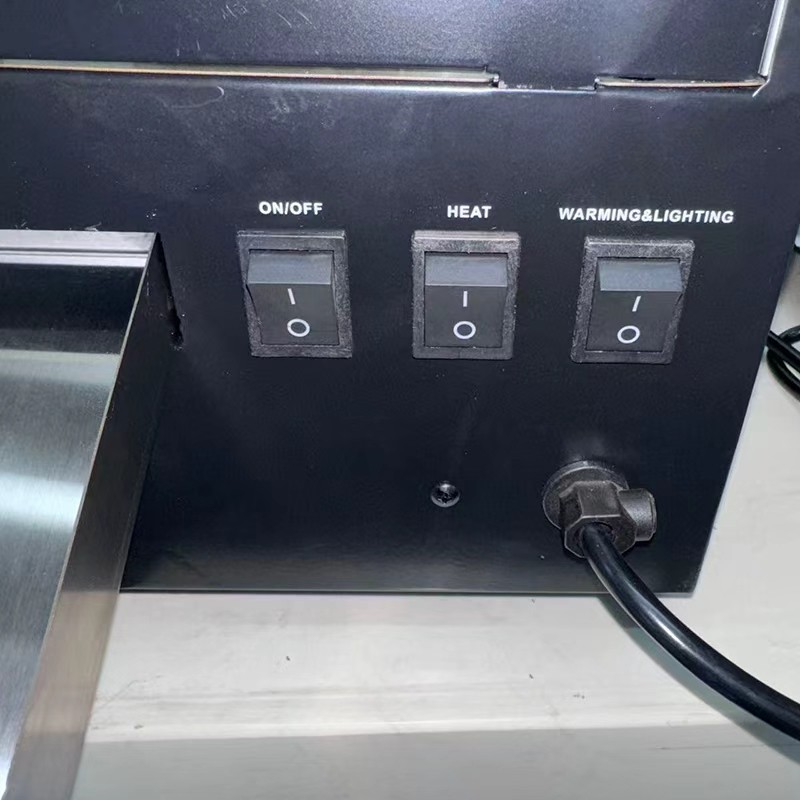

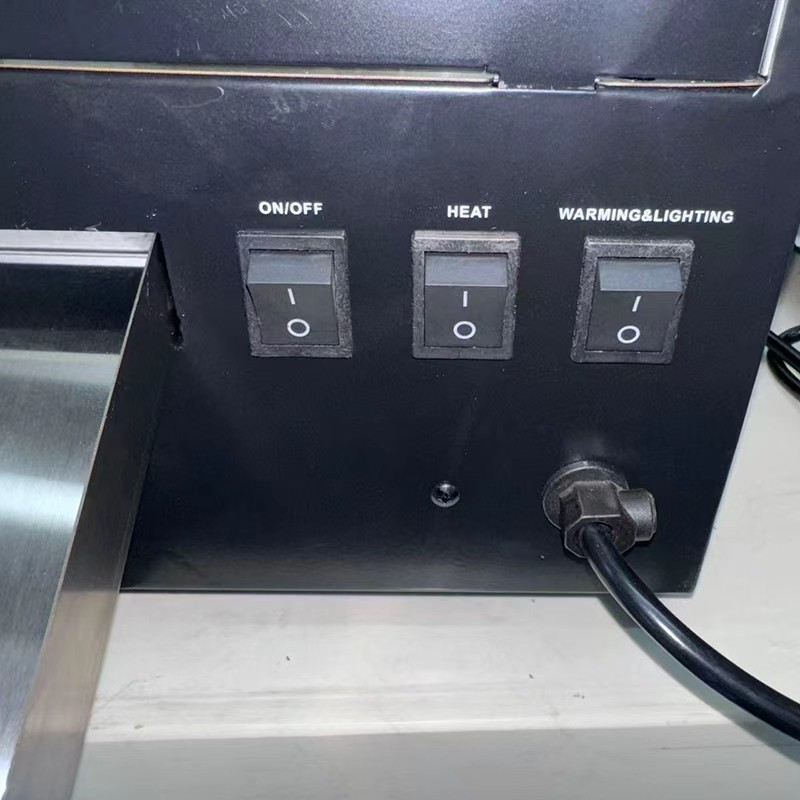

The MLP-BJS Commercial Popcorn Popper Machine is a compact, visually appealing snack appliance designed for quick and consistent popcorn production in commercial venues. With an 8oz kettle, transparent curved glass housing, and simple top-panel controls, it provides a clear operational view and an intuitive user experience. The warming system and interior lighting preserve popcorn freshness, ensuring customers receive crisp, warm servings throughout the day. Its cleanable structure and efficient heating technology make it suitable for continuous operation during busy business hours.

Commercial Popcorn Popper Machine Parameter

| Model | MLP-BJS |

| Name | Popcorn Machine |

| Voltage/Frequency | 220V/50Hz |

| Power | 1.305W |

| Dimension | 423*470*720mm |

| Packing Size | 475*520*770mm |

| Usage | Snack Machine |

| Feature | Nice Appearance,big Volume,efficient Popcorn Making,also Keep Warming. |

| Warranty | 1 Year |

| N.W/G.W | 25kg/27kg |

Commercial Popcorn Popper Machine Features

Large Capacity

The 8oz kettle supports continuous popping cycles, delivering approximately 120–150 servings per hour depending on kernel size and oil ratio. This allows operators to meet rush-hour demand without interruption. Laboratory tests show that an 8oz kettle typically yields 220–240 g of popped corn per cycle, enabling stable production output with minimal downtime.

Fast Heating

The 1305W heating system raises kettle temperature to optimal popping range (180–200°C) within minutes, shortening preheat time and improving efficiency. Continuous-cycle testing demonstrates that the machine can complete a full popping cycle in 2–3 minutes, significantly faster than conventional 5–6 minute poppers, reducing energy consumption by more than 30%.

Clear Visibility

The integrated curved tempered glass provides over 90% light transmittance, giving users full visibility of the popping process and improving customer appeal in commercial environments. The viewing window also passes durability tests with impact resistance above 2.5 J, ensuring safety and long-term performance even during frequent use.

Stable Insulation

The built-in warming light and bottom heater maintain popcorn temperature at 55–65°C, preventing moisture absorption and preserving crispness for extended periods. Thermal retention tests indicate that popcorn stored within this temperature range retains its desirable texture for up to 45 minutes compared to 15–20 minutes without heating assistance.

Easy Cleaning

The removable oil/crumbs box collects residue efficiently, reducing cleaning time by approximately 40% based on operator testing. The non-stick kettle coating maintains surface friction coefficients below 0.2, preventing buildup and allowing operators to wipe the surface clean quickly after each batch.

Cinemas

Movie theaters benefit from the machine’s 2–3 minute popping cycle, which allows frequent replenishment during peak showtimes. With capacity to serve hundreds of customers per hour, the machine supports high-traffic concessions while maintaining consistent product quality and lower electricity consumption compared with slower poppers.

Snack Shops

Small retail snack businesses can use this machine to produce fresh popcorn in real time, enhancing aroma-based sales. Shops serving 50–100 customers per hour can maintain output without quality drop because the warming system keeps popcorn crisp and ready for immediate serving, supporting efficient turnover and stable sales.

Event Booths

Temporary booths at fairs, exhibitions, or outdoor markets can rely on the machine’s compact size and durable structure. The 25–27 kg weight ensures stability while remaining portable for frequent relocation. Its high-visibility glass design attracts customers, and the rapid popping cycle helps operators meet sudden crowd surges efficiently.

Commercial Popcorn Popper Machine More Details about

DINGFENG POPULAR PRODUCTS

Jiangmen Dingfeng Saving Kitchen Electric Co., Ltd. owns a modern production factory covering an area of over 10,000 square meters. Inside the factory, more than 80 well - trained employees perform their respective duties, forming a professional and efficient production team. Since its establishment, with exquisite technology and innovative ideas, the company has successfully produced more than 1000 different types of products. The rich variety of products fully demonstrates our strong production capacity and innovative vitality.

The company's main business is extensive, covering various kitchen electrical products. The product range is rich and diverse, including desktop luxury stoves cooker range, griddle, waffle baker, barbecue grills, deep fryers, panini grills, ice cream machine etc., fast food equipment, snack equipment, refrigeration, and other general commercial kitchen equipment. We have cooperated with more than 200 well-known brands around the world and have won a good reputation in the international market with our high-quality products and services, becoming a trusted partner for many customers. Our brand MARUPIN is widely well known by customers domestic and overseas.

Our company has invested heavily in introducing advanced equipment, equipped with world-class CNC punching, cutting, bending, and welding series processing equipment, and has strong technical strength to adapt to product development, technical correction, and product transformation. Every product needs to go through several strict quality inspection processes to ensure that the product has the best appearance and performance, delivering the most cost-effective product to every user and providing reliable product guarantee for customers.