Industrial Commercial Panini Sandwich Grooved Grill

Category: Promotion

-

+86-13929587046 WhatsApp

-

dfwuch67@gmail.com Email

The overall structure of Panini Contact Grill is made of corrosion-resistant stainless steel. The heating area is divided into two upper and lower cast iron full-grooved grill plates, covered with high-temperature resistant Teflon coating. The upper plate measures 34×22cm, the lower plate measures 34.5×23.5cm, the overall size of the equipment is 430×370×190mm, and the net weight is 15kg. It is equipped with a temperature controller, heating indicator light, anti-scalding handle and non-slip rubber foot pad, which is an ideal choice for professional kitchens and efficient operation scenarios.

Industrial Commercial Panini Sandwich Grooved Grill Parameter

| Model | MLP-811E |

| Name | Large Electric Single Contact Full Grooved Grill |

| Voltage/Frentcy | 220~240V/50~60Hz |

| Pwoer | 2.3KW |

| Dimension | 430*370*190mm |

| Packing Size | 487*427*260mm |

| Usage | Food Industry Equipment |

| Feature | High Productivity |

| Warranty | 1 Year |

| N.W/G.W | 15kg/16.5kg |

Industrial Commercial Panini Sandwich Grooved Grill Features

High power output improves production efficiency

Panini Contact Grill is equipped with 2.3KW heating power and operates at 220-240V/5060Hz voltage. It can quickly heat the upper and lower grill plates to the set temperature in a short time. Compared with conventional 1.8KW models, it heats up faster and keeps the heat more stable, which is particularly suitable for continuous operation during peak hours and increases the number of meals per unit time.

Wide baking trays support various combinations

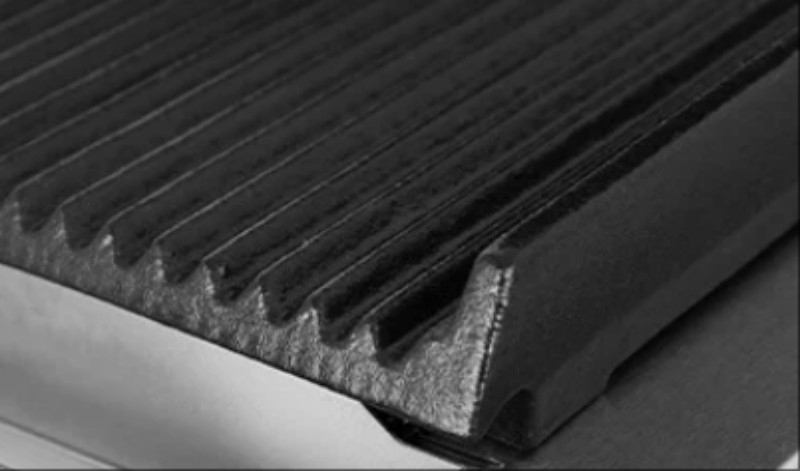

The upper baking tray of Panini Contact Grill is 34×22cm in size, and the lower baking tray is 34.5×23.5cm. It can handle large-sized panini or two medium sandwiches at a time. With the upper and lower full groove embossing design, it can form a unique texture on the surface of the food, enhancing the appearance and customer appetite.

Teflon anti-stick technology reduces the difficulty of cleaning

The upper and lower baking trays of Panini Contact Grill are covered with high-temperature Teflon coating to prevent the food from adhering to the metal surface during high-temperature heating. After cooking, just wipe it lightly with a damp cloth to complete the cleaning, reducing manual cleaning time and avoiding scratching the baking tray to affect the heating effect.

Zoned temperature control + status indicator design

The panel is equipped with an adjustable temperature control knob, and the operating temperature range is 30°C to 260°C. Users can accurately set the heating intensity according to the type of food. During the heating process, the status indicator light reminds you at any time whether the equipment is in the heating working state, improving operational safety and visibility.

Multi-layer thickness structure enhances the quality of finished products

The upper plate thickness of Panini Contact Grill is 4.5cm, the lower plate thickness is 3.5cm, and the upper cavity height is 4.5cm and the lower cavity height is 1.5cm. It can easily adapt to multi-layer food combinations, such as thick-cut steak + cheese + vegetable combination, to achieve a finished product with rich layers, crispy outside and tender inside.

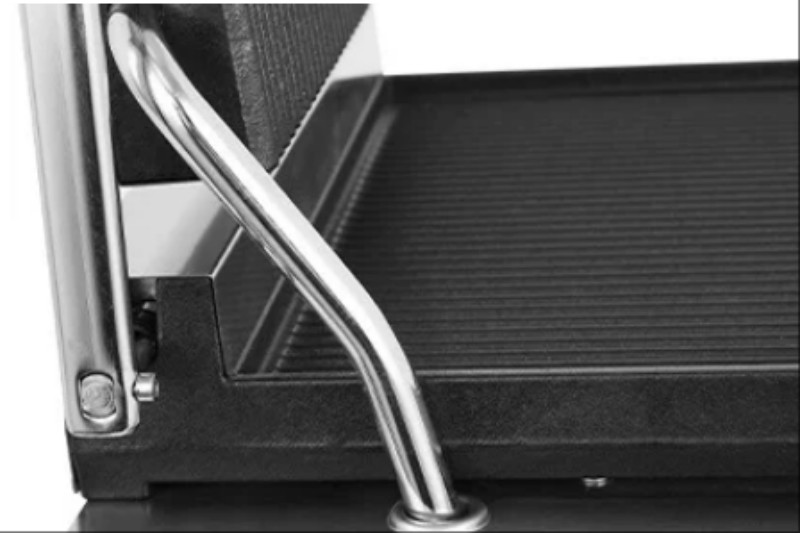

Anti-scalding operating handle improves safety level

Panini Contact Grill is equipped with a high-strength heat-insulating operating handle, which is wrapped with anti-slip material, high temperature resistant and non-conductive. Even after the equipment has been running for a long time, it can be held safely to avoid scalding accidents. It is suitable for continuous opening and closing operations in busy operating environments.

Stable structure and convenient transportation

The body design is compact and sturdy. The net weight of Panini Contact Grill is 15kg. With anti-slip rubber foot pads, it is stable and does not shift. At the same time, the packaging size is only 487×427×260mm, which is convenient for international logistics transportation and warehousing, reducing transportation costs.

Chain coffee brand stores

Costa Coffee and Pacific Coffee and other chain brands widely use Panini Contact Grill to make hot paninis and sandwiches made to order, meeting customers' needs for fast food delivery while maintaining the crispy texture of the bread and the heat of the ingredients.

Convenience store backstage hot food processing area

Convenience store brands such as FamilyMart and Lawson use Panini Contact Grill to bake and heat ready-to-eat hot foods (such as chicken panini and vegetable toast) during brunch hours, improving the experience of making them on the spot and enhancing the appeal of the products.

Office building central kitchen

In the central kitchen of the office building, Panini Contact Grill is used to batch press hot sandwiches in the lunch boxes of corporate employees, which is especially suitable for large-scale preparation and high-speed delivery scenarios. The equipment heats evenly, saving waiting time.

Campus cafeteria snack stalls

At the hot food window of university or middle school cafeterias, Panini Contact Grill is often used to make simple and quick hot sandwiches or vegetarian paninis, helping students to buy quickly and eat conveniently, and also helping operators control the quality and speed of food delivery.

American restaurant open kitchen

American chain restaurants such as Hard Rock Café and TGI Friday's often place Panini Contact Grill in the front open kitchen to press snacks such as cheese beef sandwiches or chicken burritos. On-site operation attracts customers' attention and increases the order rate.

High-speed rail station business travel catering point

At the high-speed rail station catering window, Panini Contact Grill can be used to bake hot bread and meat combinations for passengers to take and eat on the spot. Through rapid heating and uniform baking, it provides efficient, high-quality and convenient hot food services for business travelers.

Frozen food factory post-heat treatment area

In frozen panini and ready-to-eat sandwich production factories that mainly export, Panini Contact Grill is used for product thermal processing and shaping. Its embossing function improves the appearance of frozen finished products and ensures standardized appearance and flavor exported to European and American markets.

DINGFENG POPULAR PRODUCTS

Jiangmen Dingfeng Saving Kitchen Electric Co., Ltd. owns a modern production factory covering an area of over 10,000 square meters. Inside the factory, more than 80 well - trained employees perform their respective duties, forming a professional and efficient production team. Since its establishment, with exquisite technology and innovative ideas, the company has successfully produced more than 1000 different types of products. The rich variety of products fully demonstrates our strong production capacity and innovative vitality.

The company's main business is extensive, covering various kitchen electrical products. The product range is rich and diverse, including desktop luxury stoves cooker range, griddle, waffle baker, barbecue grills, deep fryers, panini grills, ice cream machine etc., fast food equipment, snack equipment, refrigeration, and other general commercial kitchen equipment. We have cooperated with more than 200 well-known brands around the world and have won a good reputation in the international market with our high-quality products and services, becoming a trusted partner for many customers. Our brand MARUPIN is widely well known by customers domestic and overseas.

Our company has invested heavily in introducing advanced equipment, equipped with world-class CNC punching, cutting, bending, and welding series processing equipment, and has strong technical strength to adapt to product development, technical correction, and product transformation. Every product needs to go through several strict quality inspection processes to ensure that the product has the best appearance and performance, delivering the most cost-effective product to every user and providing reliable product guarantee for customers.