Large Contact Grill

Category: Promotion

-

+86-13929587046 WhatsApp

-

dfwuch67@gmail.com Email

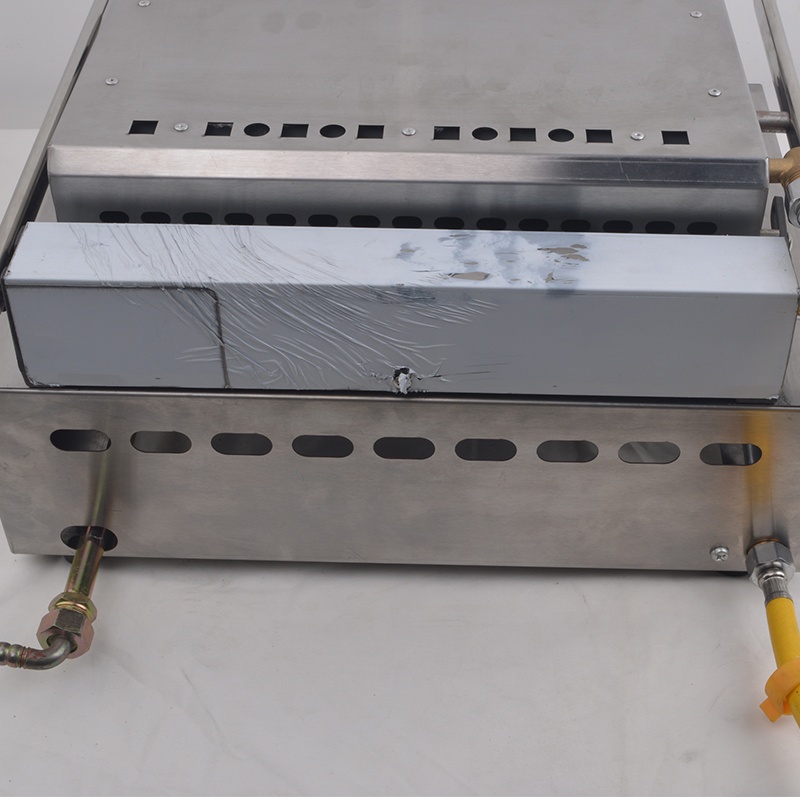

The upper and lower grill plates of Large Gas Contact Grill are made of cast iron and adopt a full groove structure. The size of the lower grill plate is 500×320mm, and the overall size is 570×468×270mm. The shell is made of high-temperature resistant metal material, equipped with convenient switches, control knobs and non-slip base. The whole machine weighs 23kg. It is a double-sided commercial pressure grilling equipment that uses liquefied petroleum gas (LPG) for combustion and heating. It is designed for high-load and high-efficiency catering environments.

Large Contact Grill Parameter

| Model | MLP-811ES |

| Name | Large Gas Contact Grill |

| Burner | 2 Burners |

| Pwoer | Gas LPG/2800Pa |

| Dimension | 570*468*270mm |

| Packing Size | 600*470*300mm |

| Usage | Food Industry Equipment |

| Feature | Easy Operation |

| Warranty | 1 Year |

| N.W/G.W | 23kg/25kg |

Large Contact Grill Features

High-temperature gas heating system heats up quickly

Large Gas Contact Grill uses 2 sets of gas burners and uses 2800Pa pressure LPG gas source. The thermal energy responds quickly and the equipment can heat up to 300℃ in a short time. Compared with electric heating equipment, gas models are suitable for commercial places with higher efficiency requirements, especially in areas without power restrictions or inconvenient natural gas supply.

Extra-large baking tray size supports multiple batch operations

The lower baking tray of Large Gas Contact Grill is 500×320mm in size, which can accommodate multiple sandwiches or whole steaks, prawns and other high-capacity ingredients at the same time. It is particularly suitable for batch pressure baking during breakfast peak or takeaway order concentration period, which greatly improves the production capacity per unit time and reduces the labor waiting cost.

Cast iron groove double-sided embossed design

The upper and lower baking plates are all full-grooved cast iron structures with good heat storage capacity and uniform heat conduction. The baking tray can produce clear stripes when it contacts the ingredients, giving meat products a professional restaurant-level visual effect, while helping to degrease the surface and improve the taste and appearance.

Precise and controllable temperature range is wide

Large Gas Contact Grill supports a wide temperature control range of 50℃ to 300℃, which can be manually adjusted through the switch and control knob. Whether it is light pressure to heat the toast crust or high temperature to lock the moisture of meat, precise firepower control can be achieved to meet the needs of making diverse dishes.

Solid structure, easy to clean and maintain

The Large Gas Contact Grill is made of corrosion-resistant stainless metal and can adapt to complex environments such as oil smoke and humidity. The grill plate can be wiped regularly, and the surface is smooth and not easy to leave food residues. With the stainless steel oil collection tank, it effectively improves the cleaning efficiency and extends the service life of the equipment.

Integrated non-slip foot pads enhance stability

The Large Gas Contact Grill is equipped with 4 thick non-slip rubber foot pads at the bottom, which can be firmly adsorbed on the operating table, effectively preventing position displacement caused by frequent opening and closing or vibration during use, improving the safety of use, and also avoiding the operator from operating errors due to equipment shaking during high-intensity use.

Chinese fast food chain stores

The back kitchens of fast food chain brands such as "Zhen Gongfu" and "Laoniangjiu" are often equipped with gas-fired pressure baking equipment for high-temperature and rapid baking of pre-prepared meats such as chicken chops and pork chops, and the set meal is highly efficient. Gas heating reacts quickly, greatly reducing customer waiting time and ensuring that the food is warm and has a consistent taste.

Cold chain food secondary processing plant

Large Gas Contact Grill can be used in cold chain food enterprises, such as "Zhengda Foods", to shape and press refrigerated or frozen meat in the secondary heat treatment section to form a standardized appearance texture and enhance the market sales appeal of the product.

American fast food franchise stores

Brand stores such as Carl’s Jr. and Wendy’s that specialize in American hamburgers and barbecues are often equipped with Large Gas Contact Grill to perform high-temperature edge sealing on beef patties, improve the appearance, lock in gravy, and keep each burger at a high level of quality.

Comprehensive catering central kitchen

The central kitchens of large chain brands, such as Yonghe King and Dicos distribution centers, will use Large Gas Contact Grill for semi-finished product heat processing, uniformly complete the initial shaping and pretreatment of meat or pastries, and improve shipment consistency and corporate standardization.

DINGFENG POPULAR PRODUCTS

Jiangmen Dingfeng Saving Kitchen Electric Co., Ltd. owns a modern production factory covering an area of over 10,000 square meters. Inside the factory, more than 80 well - trained employees perform their respective duties, forming a professional and efficient production team. Since its establishment, with exquisite technology and innovative ideas, the company has successfully produced more than 1000 different types of products. The rich variety of products fully demonstrates our strong production capacity and innovative vitality.

The company's main business is extensive, covering various kitchen electrical products. The product range is rich and diverse, including desktop luxury stoves cooker range, griddle, waffle baker, barbecue grills, deep fryers, panini grills, ice cream machine etc., fast food equipment, snack equipment, refrigeration, and other general commercial kitchen equipment. We have cooperated with more than 200 well-known brands around the world and have won a good reputation in the international market with our high-quality products and services, becoming a trusted partner for many customers. Our brand MARUPIN is widely well known by customers domestic and overseas.

Our company has invested heavily in introducing advanced equipment, equipped with world-class CNC punching, cutting, bending, and welding series processing equipment, and has strong technical strength to adapt to product development, technical correction, and product transformation. Every product needs to go through several strict quality inspection processes to ensure that the product has the best appearance and performance, delivering the most cost-effective product to every user and providing reliable product guarantee for customers.