Professional Full Grooved Single Contact Electric Gril

Category: Promotion

-

+86-13929587046 WhatsApp

-

dfwuch67@gmail.com Email

Silver Contact Grill is made of high-quality stainless steel with a silver luster. The heating area includes an upper baking tray (23×23cm) and a lower baking tray (21.5×21.5cm). Both sides are fully grooved. The baking tray body is made of cast iron and covered with Teflon coating. The whole machine is equipped with anti-scalding handles, independent thermostats, indicator lights, suspension shaft system, stainless steel oil collection tank and non-slip rubber foot pads. The size is 305×370×190mm and the net weight is 10kg. It is an electric heating contact baking tray equipment designed for professional kitchens and commercial catering scenes.

Professional Full Grooved Single Contact Electric Gril Parameter

| Model | MLP-811 |

| Name | Electric Single Contact Full Grooved Grill |

| Voltage/Frentcy | 220~240V/50~60Hz |

| Pwoer | 1.8KW |

| Dimension | 305*370*190mm |

| Packing Size | 435*360*260mm |

| Usage | Food Industry Equipment |

| Feature | Easy Operation |

| Warranty | 1 Year |

| N.W/G.W | 10kg/11.5kg |

Professional Full Grooved Single Contact Electric Gril Features

High-efficiency thermal conductive Teflon coating

The surface of the cast iron heating plate is sprayed with food-grade Teflon coating, which not only makes the food less likely to stick during the heating process, but also significantly improves the heat conduction efficiency. The coating is resistant to high temperatures and can withstand a working environment of up to 260°C, effectively improving the speed of serving meals and suitable for use during peak hours.

Durable stainless steel body structure

Silver Contact Grill is made of 304 stainless steel, which has excellent corrosion resistance and is not easy to rust even in a humid and fume environment for a long time. The silver brushed surface not only improves the grade of the equipment, but also facilitates daily scrubbing and maintenance, ensuring the durability of the product.

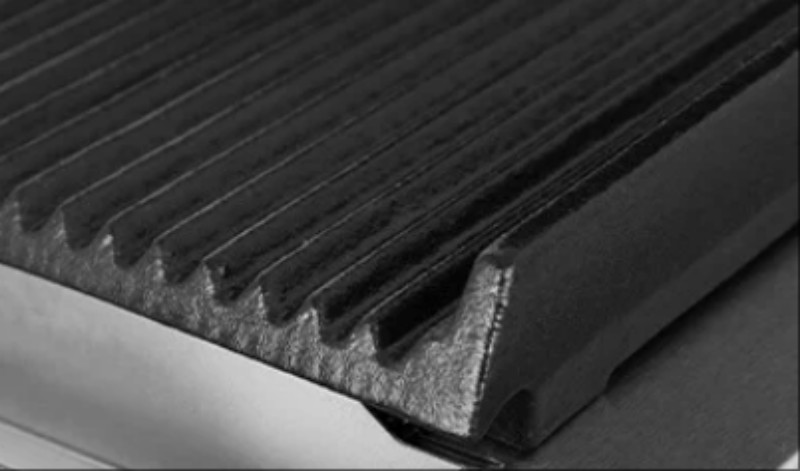

Full groove double-sided baking plate design

The upper plate is 23×23cm and the lower plate is 21.5×21.5cm, both of which are full groove cast iron baking plates, which can bake neat textures on the surface of meat, sandwiches, and vegetables, making the finished product more beautiful. Heating on both sides at the same time shortens the production time and improves work efficiency.

Adjustable temperature control system

The built-in temperature controller has a temperature range of 30°C to 260°C, which can be flexibly adjusted according to the baking requirements of different ingredients. The panel is equipped with a temperature control knob and a heating indicator light, so that the operator can clearly grasp the current working status and improve the convenience of use.

Humanized anti-scalding handle design

Silver Contact Grill uses an operating handle wrapped with heat-insulating material, which can be safely held even after the equipment has been running for a long time, effectively preventing the operator from being scalded. The handle is ergonomically designed, opens and closes smoothly, and reduces hand fatigue.

Removable oil collection tank design

The bottom of the Silver Contact Grill is equipped with a stainless steel oil collection tank, which can effectively collect excess grease generated during the grilling process to prevent the food from greasy due to grease accumulation. At the same time, it is easy to disassemble and clean, keeping the whole machine clean and hygienic, in line with food processing standards.

Stable rubber foot pad design

The bottom of the Silver Contact Grill is equipped with four non-slip rubber foot pads, which can effectively prevent the equipment from sliding during operation and improve operational stability. At the same time, it has a certain shock-absorbing effect, which can reduce vibration and noise, creating a quieter kitchen environment.

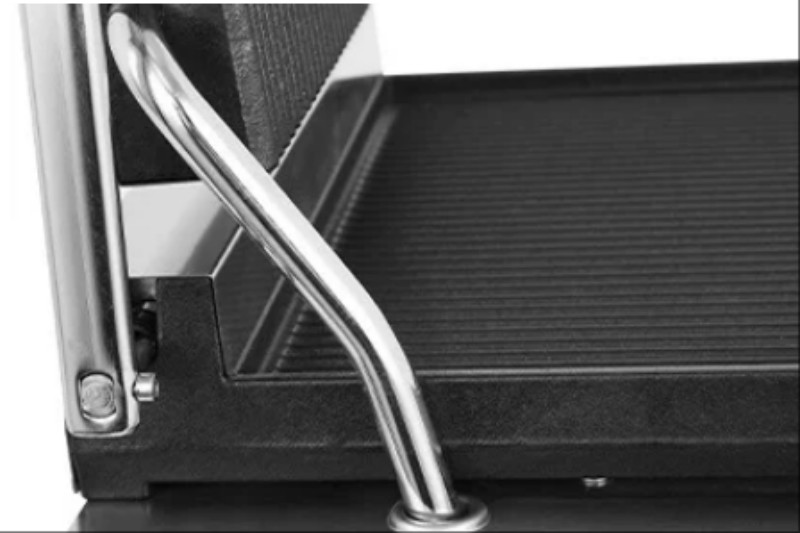

Durable cable and suspension shaft structure

The interior of the Silver Contact Grill is equipped with high-temperature resistant and thickened cable pipelines to extend the service life and reduce the risk of electrical failure. The upper cover adopts a suspension shaft system, which can be fixed at any angle, making it easy to flip, check or take and put ingredients, and improve overall operational flexibility.

Café application

The Silver Contact Grill is widely used in cafes to quickly heat or press panini, toast and breakfast sandwiches. Its double-sided heating design allows the food to achieve crispy crust and hot fillings in a short time, improving customer satisfaction and turnover efficiency.

Fast food chain stores

In fast food brands such as Subway, Silver Contact Grill is used to efficiently make hot food such as chicken rolls, grilled steak burgers, etc. It can complete the surface flavor sealing and internal ripening of ingredients within a few minutes, matching the fast-paced operation process and ensuring food quality.

Commercial center food court

Food court stalls often use Silver Contact Grill to reheat and shape pre-prepared refrigerated ingredients, such as grilled sausages, vegetarian steaks, tortillas, etc. With its precise temperature control and high thermal efficiency, it ensures that the food is sold immediately after it is hot, shortening the waiting time for customers.

Star hotel kitchen

In the kitchens of high-end hotels such as Marriott and Hilton, Silver Contact Grill is used for breakfast and all-day snack services. It is particularly suitable for processing sandwiches, grilled vegetables and small pieces of meat to ensure the consistency and high-level taste of the dishes.

Western restaurant open kitchen

Some open western restaurants that focus on visual experience, such as Outback Steakhouse, use this equipment for live grilling demonstrations. The texture of the baking pan can effectively improve the appearance and flavor of dishes such as steak and chicken breast, and enhance the customer experience.

Food factory pre-processing line

Silver Contact Grill is also used in the heat treatment of pre-made dishes in food factories. Its wide temperature control range and uniform contact baking provide stable processing conditions for products such as frozen panini and pre-made beef patties.

Convenience store hot food area

Brands such as 7-Eleven use Silver Contact Grill to make freshly baked hot dogs or grilled chicken thighs in the back field. The embossed heating improves the appearance and taste of hot food, effectively attracting customers to buy it immediately, and increasing the unit square meter efficiency income.

DINGFENG POPULAR PRODUCTS

Jiangmen Dingfeng Saving Kitchen Electric Co., Ltd. owns a modern production factory covering an area of over 10,000 square meters. Inside the factory, more than 80 well - trained employees perform their respective duties, forming a professional and efficient production team. Since its establishment, with exquisite technology and innovative ideas, the company has successfully produced more than 1000 different types of products. The rich variety of products fully demonstrates our strong production capacity and innovative vitality.

The company's main business is extensive, covering various kitchen electrical products. The product range is rich and diverse, including desktop luxury stoves cooker range, griddle, waffle baker, barbecue grills, deep fryers, panini grills, ice cream machine etc., fast food equipment, snack equipment, refrigeration, and other general commercial kitchen equipment. We have cooperated with more than 200 well-known brands around the world and have won a good reputation in the international market with our high-quality products and services, becoming a trusted partner for many customers. Our brand MARUPIN is widely well known by customers domestic and overseas.

Our company has invested heavily in introducing advanced equipment, equipped with world-class CNC punching, cutting, bending, and welding series processing equipment, and has strong technical strength to adapt to product development, technical correction, and product transformation. Every product needs to go through several strict quality inspection processes to ensure that the product has the best appearance and performance, delivering the most cost-effective product to every user and providing reliable product guarantee for customers.