Electric Lolly Waffle Maker

Category: Waffle Maker

-

+86-13929587046 WhatsApp

-

dfwuch67@gmail.com Email

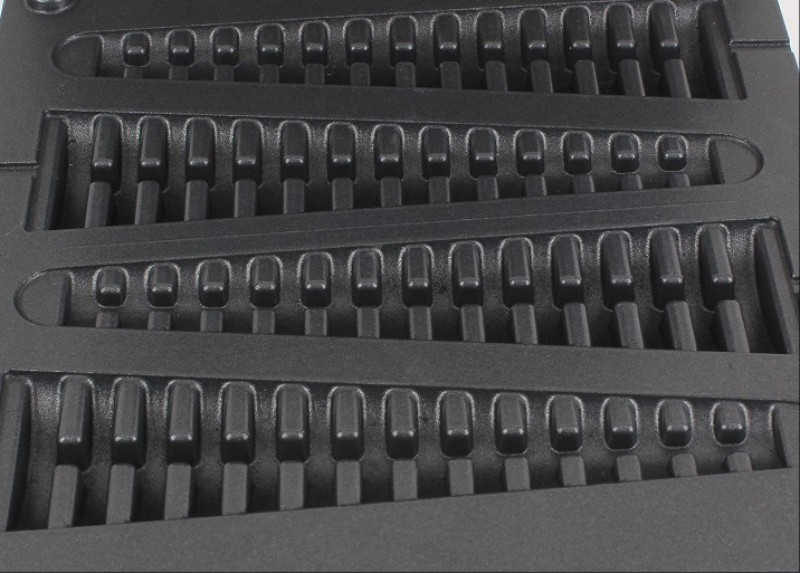

The baking area is made of aluminum plate with Teflon coating, combined with a stainless steel shell structure. The baking tray is a 26.8cm × 26.8cm square pattern, and the interior is divided into four "fish scale" alveolar structure waffle molds, each grid size is 22.5cm × 6cm, and four long waffles can be baked at the same time. The two sides are equipped with stainless steel heating elements, the front is equipped with a knob-type physical switch, a timer (0-5 minutes) and a working status indicator light, and the bottom is equipped with a non-slip rubber foot pad. The device is moderate in size (320*450*280mm) and weighs 8.5kg. It is suitable for installation in dessert shops, catering kitchens, pop-up stalls, campus canteens and other environments with limited space but high output requirements.

Electric Lolly Waffle Maker Parameter

| Model | MLP-118 |

| Name | Electric Lolly Waffle Maker |

| Voltage/Frentcy | 220~240V/50~60Hz |

| Pwoer | 1.5KW |

| Dimension | 320*450*280mm |

| Packing Size | 500*365*305mm |

| Usage | Food Industry Equipment |

| Feature | High Productivity |

| Warranty | 1 Year |

| N.W/G.W | 8.5kg/10kg |

Electric Lolly Waffle Maker Features

Four-grid large-size baking plate, double efficiency suitable for mass production

One of the biggest highlights of Electric Lolly Waffle Maker is its integrated four-grid large-size baking tray design, which can bake four 22.5 cm long stick-shaped waffles in one operation, which greatly improves the production efficiency per unit time compared to the traditional two-grid or single-grid structure. This kind of fish scale pattern die is not only beautiful and generous, but also can increase the crispness of the product surface, improve visual appeal and taste performance. It is suitable for commercial operation models with fast food delivery and uniform specifications, such as chain waffle stores, night market stalls, dessert processing workshops, etc. Each finished product is suitable for stick sales, which is convenient for customers to buy and eat or take away. It is also convenient to match chocolate, jam, ice cream and other auxiliary materials for personalized decoration to expand sales models. The four-grid integrated structure baking tray can also effectively reduce the heat loss caused by frequent opening and closing of the machine, thereby reducing energy consumption and improving the thermal efficiency of continuous baking, so that Electric Lolly Waffle Maker can continue to produce stably even in an all-weather operation environment.

Teflon non-stick material, easier cleaning, more complete products

Electric Lolly Waffle Maker uses imported Teflon coating material, which has strong non-stick properties and can keep the batter from sticking to the baking pan surface at high temperatures. After the batter expands to shape, it can be easily demolded, not easy to break or crack, and maximizes the product yield. This coating not only improves the appearance integrity and uniformity of the product, but also significantly reduces the adhesion of baking residues, making it easier to clean and maintain daily. Traditional metal baking pans often have carbon deposits, scorch marks or sticking problems after long-term use, while the Teflon layer can be kept clean for a long time. Just wipe with a soft cloth to remove the residue, eliminating the trouble of using steel wool to scrub, saving a lot of manpower and water and electricity costs. At the same time, the material has good thermal conductivity and high temperature resistance, and can evenly transfer heat to the entire baking area of the plate to avoid partial over-scorching or undercooking. As a food-grade material, Teflon meets international safety standards and is suitable for export to the European and American markets. It is the preferred panel material for commercial food equipment.

Precise temperature control and timing, built-in limit protection is safer

Electric Lolly Waffle Maker is equipped with a high-precision knob-type thermostat, which supports flexible setting of operating temperature in the range of 50℃ to 300℃, suitable for baking needs of various batter recipes. Users can freely adjust the temperature control parameters according to the sugar content, moisture and density of different raw materials to achieve the most ideal color, texture and taste. Electric Lolly Waffle Maker is also equipped with a 0-5 minute timer to avoid burning or wasting products due to forgetting the time. To ensure operational safety, the Electric Lolly Waffle Maker has an integrated electrical component safety limit function. When the temperature is too high or the line is abnormal, it will automatically cut off the power to prevent component damage and personal injury, reducing the risk of use. The wire connecting the upper and lower baking trays is wrapped with a stainless steel snake hose, which can effectively prevent damage caused by high temperature erosion, accidental contact and cleaning misoperation, further improving the safety level of the equipment. This design is particularly suitable for working environments with frequent changes in kitchen staff or uneven user experience. Even beginners can quickly master the operation process to ensure product stability and operational safety.

Suitable for standardized production in shopping malls and dessert shops

As waffle sticks become increasingly popular in the consumer market, more and more brands are incorporating them into their main product lines. Electric Lolly Waffle Maker is a commercial-grade device born for this trend. Its four-grid structure ensures high-frequency production efficiency. At the same time, the product has a unified appearance and standard specifications, which is very suitable for cooperating with the brand's central kitchen or store SOP production process to promote production consistency between chain stores. The equipment uses Teflon coating for easy cleaning and adjustable temperature control timing. Even if employees change frequently, they can quickly master the use skills and reduce human errors. With other supporting equipment such as display cabinets, insulation furnaces, cream whipping machines, etc., a complete waffle dessert sales scene can be created to increase customer unit price and customer stickiness.

Suitable for high-frequency operations in mobile stalls in night markets

For high-traffic scenes such as night markets, food festivals, and exhibitions, production speed and visual appeal are particularly important. Electric Lolly Waffle Maker can achieve rapid heating and batch production to meet high-frequency order needs. The Electric Lolly Waffle Maker heats up quickly and only needs a short preheating time to enter the working state; at the same time, the four grids are produced simultaneously, which significantly shortens the waiting time for customers. With sticks and paper bag packaging, it is convenient for handheld sales and enhances the convenient experience. The Electric Lolly Waffle Maker is of moderate size and light weight, suitable for transportation with vehicles and temporary exhibitions. It only needs mains power to start operation later, without complicated installation. The overall maintenance cost is low, suitable for start-up self-employed individuals and stall operators as the main equipment investment.

Suitable for prefabricated dessert factory production enterprises

As a high-capacity and high-stability equipment, the Electric Lolly Waffle Maker is also very suitable for batch production of prefabricated waffle embryos in food processing plants or cold chain enterprises. The Electric Lolly Waffle Maker has standard specifications and uniform shapes, which helps to automate the subsequent cooling, packaging and frozen storage processes. The products can be exported to the European and American markets or supplied to offline chain stores to meet the "hot and ready to eat" consumption model. When used with other surface treatment, grouting and cooling equipment, it can also build a small central factory to support OEM orders or brand-owned mass production. Its stable process and low operating threshold also save factories a lot of costs on personnel training, improving overall production line efficiency and return on investment.

DINGFENG POPULAR PRODUCTS

Jiangmen Dingfeng Saving Kitchen Electric Co., Ltd. owns a modern production factory covering an area of over 10,000 square meters. Inside the factory, more than 80 well - trained employees perform their respective duties, forming a professional and efficient production team. Since its establishment, with exquisite technology and innovative ideas, the company has successfully produced more than 1000 different types of products. The rich variety of products fully demonstrates our strong production capacity and innovative vitality.

The company's main business is extensive, covering various kitchen electrical products. The product range is rich and diverse, including desktop luxury stoves cooker range, griddle, waffle baker, barbecue grills, deep fryers, panini grills, ice cream machine etc., fast food equipment, snack equipment, refrigeration, and other general commercial kitchen equipment. We have cooperated with more than 200 well-known brands around the world and have won a good reputation in the international market with our high-quality products and services, becoming a trusted partner for many customers. Our brand MARUPIN is widely well known by customers domestic and overseas.

Our company has invested heavily in introducing advanced equipment, equipped with world-class CNC punching, cutting, bending, and welding series processing equipment, and has strong technical strength to adapt to product development, technical correction, and product transformation. Every product needs to go through several strict quality inspection processes to ensure that the product has the best appearance and performance, delivering the most cost-effective product to every user and providing reliable product guarantee for customers.