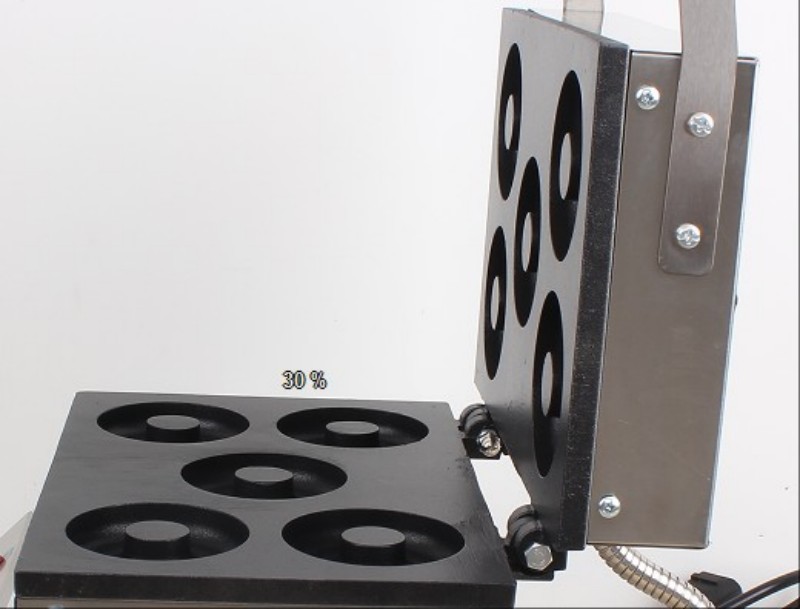

Five Grids Electric Donuts Grill

Category: Waffle Maker

-

+86-13929587046 WhatsApp

-

dfwuch67@gmail.com Email

The main body size of Five Grids Electric Donuts Grill is 410*385*320mm. The baking area is an integrated aluminum baking tray with a food-grade Teflon non-stick coating on the surface. There are 5 donut molds with a diameter of 8cm in the baking tray area. The upper cover can be opened smoothly to the specified angle. The control panel is concentrated in front of the device. It adopts a knob design with clear temperature and time scales. There is a power switch and indicator light on the left. The handle is made of high-density heat-insulating plastic, which is non-slip and scalding. It is an electric heating device designed for commercial dessert making scenes. The whole machine is made of aluminum plate and stainless steel structure, taking into account the thermal conductivity efficiency and the durability of the shell.

Five Grids Electric Donuts Grill Parameter

| Model | MLP-Q5 |

| Name | Five Grids Electric Donuts Grill |

| Voltage/Frentcy | 220~240V/50~60Hz |

| Pwoer | 1.7KW |

| Dimension | 410*385*320mm |

| Packing Size | 37.5*36.5*27.5mm |

| Usage | Food Industry Equipment |

| Feature | High Productivity |

| Warranty | 1 Year |

| N.W/G.W | 7.3kg/9kg |

Five Grids Electric Donuts Grill Features

Accurate temperature control to improve product stability

Five Grids Electric Donuts Grill is equipped with a highly sensitive mechanical temperature control system with a temperature adjustment range of 50℃ to 300℃. Users can set the required heating intensity according to different batter recipes, baking requirements and taste. Five Grids Electric Donuts Grill uses double-layer spiral electric heating tubes embedded in the upper cover and base. With the metal heat conduction plate, it can achieve rapid heating within 5 minutes, with a temperature difference control accuracy of ±5℃, and can maintain stable temperature even in continuous use. This temperature control capability is particularly suitable for dessert crafts that have high requirements for the crispness of the product shell and internal humidity. The long-time timer supports adjustment between 0 and 5 minutes, which is convenient for operators to set the baking time of each batch of donuts, reduce manual supervision time, avoid human errors causing burnt or undercooked, and improve operation consistency.

Efficient production to meet the needs of commercial kitchens

Five Grids Electric Donuts Grill can produce 5 standard 8cm diameter donuts per round of baking. With a regular baking time of 3 minutes, the theoretical production capacity per hour can reach 90~100, which is much higher than traditional hand-made molds or household single-hole electric furnaces. This high-frequency production rhythm is particularly suitable for high-traffic scenes such as dessert chains, university canteens, and airport convenience stores, bringing efficient turnover capabilities to kitchen operations. At the same time, the equipment supports long-term continuous operation, and its electric heating system has been professionally adjusted to ensure that even if it works continuously for several hours, the equipment can maintain stable performance without fluctuations, and there will be no shutdown problems caused by overheating of the heating element, which is suitable for all-weather operation mode.

Safety-enhanced design, suitable for various commercial environments

Five Grids Electric Donuts Grill adopts multiple protection mechanisms in electrical safety. First, the equipment is equipped with an electrical component safety limiter, which will automatically cut off the circuit to prevent damage to the equipment once the internal voltage or temperature fluctuates abnormally. Secondly, all wire connection parts are wrapped with stainless steel metal hoses to effectively prevent external factors such as oil, water vapor, etc. common in the kitchen from corroding the wires, while reducing safety hazards such as sparks and short circuits. The non-slip rubber foot pads further enhance the stability of use, and can remain stable even on a slippery workbench or cart, ensuring that there is no sliding or tipping during busy working conditions. This series of safety designs not only makes the equipment meet export standards such as CE, but also wins the purchasing confidence of many professional buyers.

Applied to the central kitchen of Dunkin' Donuts chain in the United States

Five Grids Electric Donuts Grill has been successfully used in the trial operation of a central kitchen in a state of Dunkin' Donuts, a well-known American donut chain brand, mainly responsible for the pre-baking of cold chain donuts in hundreds of stores every day. The efficient production capacity of the equipment helps the factory produce more than 5,000 donut blanks every day, which are then uniformly refrigerated and transported to terminal stores for reheating and sale. The non-stick mold and temperature control performance of Five Grids Electric Donuts Grill effectively improve the completeness rate of finished products out of the mold, reduce manual finishing and scrap rate, and provide strong support for the brand's standardized production system.

Applied to Grab&Go food stalls in Singapore Changi Airport

Five Grids Electric Donuts Grill was selected for passengers' on-demand donut product line in multiple Grab&Go fast food windows in Singapore Changi Airport. The equipment has a compact structure and fast heating, which can meet the needs of fast food delivery during peak flight hours. The "freshly baked donuts" series launched with Five Grids Electric Donuts Grill has become a hot item in airport fast food, which not only drives the overall order conversion rate, but also enhances the brand image. As the airport has extremely high requirements for equipment safety standards, the electrical protection and anti-slip structure of the product have been highly recognized by the on-site audit.

Applied to the teaching and training room of Osaka Dessert School in Japan

In a dessert vocational college in Osaka, Japan, Five Grids Electric Donuts Grill is used as a teaching and training equipment for students to participate in the basic dessert making course. The school focuses on operating skills training and requires the equipment to be simple to operate and highly safe, which can meet the needs of a large number of students for repeated training at the same time. Five Grids Electric Donuts Grill uses knob operation and visual indicator light design to enable students to accurately control the heat and time even without experience, enhancing the visualization and standardization of the teaching process. At the same time, the easy-to-clean nature of the equipment also simplifies the after-school maintenance process.

DINGFENG POPULAR PRODUCTS

Jiangmen Dingfeng Saving Kitchen Electric Co., Ltd. owns a modern production factory covering an area of over 10,000 square meters. Inside the factory, more than 80 well - trained employees perform their respective duties, forming a professional and efficient production team. Since its establishment, with exquisite technology and innovative ideas, the company has successfully produced more than 1000 different types of products. The rich variety of products fully demonstrates our strong production capacity and innovative vitality.

The company's main business is extensive, covering various kitchen electrical products. The product range is rich and diverse, including desktop luxury stoves cooker range, griddle, waffle baker, barbecue grills, deep fryers, panini grills, ice cream machine etc., fast food equipment, snack equipment, refrigeration, and other general commercial kitchen equipment. We have cooperated with more than 200 well-known brands around the world and have won a good reputation in the international market with our high-quality products and services, becoming a trusted partner for many customers. Our brand MARUPIN is widely well known by customers domestic and overseas.

Our company has invested heavily in introducing advanced equipment, equipped with world-class CNC punching, cutting, bending, and welding series processing equipment, and has strong technical strength to adapt to product development, technical correction, and product transformation. Every product needs to go through several strict quality inspection processes to ensure that the product has the best appearance and performance, delivering the most cost-effective product to every user and providing reliable product guarantee for customers.