Rotary Waffle Maker

Category: Waffle Maker

-

+86-13929587046 WhatsApp

-

dfwuch67@gmail.com Email

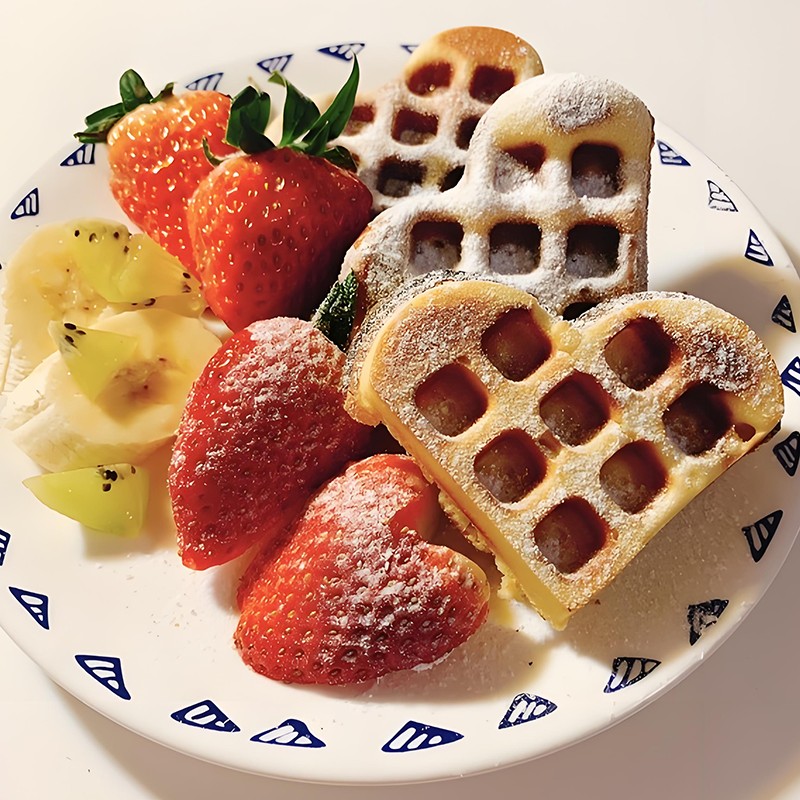

The overall size of the Rotary Waffle Maker is 250×330×255mm. The shell is made of high-strength stainless steel. The diameter of the waffle baking tray is 18.5cm, and the size of each small grid is 8.5×8.8cm. The surface is covered with food-grade Teflon non-stick coating. The rotating structure supports 180-degree flip heating of the upper and lower baking trays. It is equipped with a precise temperature control knob (50-300℃) and a 05-minute timer. The panel-integrated power switch handle is made of heat-insulating bakelite. It is a compact and efficient rotary electric waffle maker designed for catering and dessert operators.

Rotary Waffle Maker Parameter

| Model | MLP-03 |

| Name | Rotary Waffle Maker |

| Voltage/Frentcy | 220~240V/50~60Hz |

| Pwoer | 1KW |

| Dimension | 250*330*255mm |

| Packing Size | 550*310*350mm |

| Usage | Snacks Food Machine |

| Feature | High Productivity |

| Warranty | 1 Year |

| N.W/G.W | 7.6kg/8.6kg |

Rotary Waffle Maker Features

1. Rotatable heating structure to achieve uniform maturity on both sides

The biggest feature of the Rotary Waffle Maker is its 360° rotatable flip structure. The structure is designed to be manually rotated to evenly heat the upper and lower baking trays to avoid the problem of partial overcooking or undercooking in the center. After rotation, the batter automatically flows to the edge of the mold, the finished product has neat edges, a fluffy and full structure, and a better taste. This function is particularly suitable for chain dessert shops or food factories that have strict requirements on product quality. It not only ensures product consistency but also improves customer satisfaction. It is an important embodiment of high-end dessert commercial equipment.

2. Teflon non-stick coating, smooth demoulding and easy cleaning

The surface of the Rotary Waffle Maker baking tray is treated with food-grade Teflon non-stick coating, which effectively prevents the batter from sticking to the bottom, improves demoulding efficiency, and reduces scrap rate. The complete waffle can be easily removed without using too much grease coating, which is conducive to healthy diet and oil control standards. At the same time, the coating has excellent high temperature resistance and is suitable for long-term and high-frequency commercial baking scenarios. When cleaning, just wipe it with a damp cloth to restore the baking tray to a new finish, saving labor costs and extending service life.

3. Independent temperature control system, fine control of temperature and time

The Rotary Waffle Maker is equipped with an independent temperature control knob with a wide adjustment range (50℃ to 300℃), which is suitable for different batter recipes and flavor control, meeting the diverse needs of light and thin taste to thick waffles. The timer function can be set in the range of 0 to 5 minutes. Users can adjust the time according to the thickness of the ingredients and the degree of baking to avoid over-baking or under-baking and improve production accuracy. The knob-type manual adjustment design is responsive, not prone to failure, and safer and more intuitive to operate.

1. Cold drink dessert shop

The Rotary Waffle Maker is particularly suitable for selling ice cream to make crispy round waffle bases as dessert bases, meeting the consumption trend of making and eating now and attracting customers to stay and consume.

2. Cafe

In cafes, the Rotary Waffle Maker can be used as a light meal supporting equipment to quickly make crispy waffles with cream, berries, etc., enrich the menu category, and increase the average customer price of afternoon tea.

3. Hotel breakfast restaurant

In hotel breakfast services, the Rotary Waffle Maker can be used in the open buffet area, where customers can watch the waffle making process to enhance the dining experience.

4. Mobile stalls or night market stalls

Rotary Waffle Maker is compact and has universal voltage, which makes it suitable for night markets, mall islands, car stalls and other scenes. It provides popular street desserts such as cream waffles and chocolate sauce waffles, bringing higher profit margins.

5. Baking teaching or hand-made workshops

For training schools or private dessert workshops, the structural design and operation process of Rotary Waffle Maker have a good teaching demonstration effect and is a standard equipment commonly used in practical courses.

DINGFENG POPULAR PRODUCTS

Jiangmen Dingfeng Saving Kitchen Electric Co., Ltd. owns a modern production factory covering an area of over 10,000 square meters. Inside the factory, more than 80 well - trained employees perform their respective duties, forming a professional and efficient production team. Since its establishment, with exquisite technology and innovative ideas, the company has successfully produced more than 1000 different types of products. The rich variety of products fully demonstrates our strong production capacity and innovative vitality.

The company's main business is extensive, covering various kitchen electrical products. The product range is rich and diverse, including desktop luxury stoves cooker range, griddle, waffle baker, barbecue grills, deep fryers, panini grills, ice cream machine etc., fast food equipment, snack equipment, refrigeration, and other general commercial kitchen equipment. We have cooperated with more than 200 well-known brands around the world and have won a good reputation in the international market with our high-quality products and services, becoming a trusted partner for many customers. Our brand MARUPIN is widely well known by customers domestic and overseas.

Our company has invested heavily in introducing advanced equipment, equipped with world-class CNC punching, cutting, bending, and welding series processing equipment, and has strong technical strength to adapt to product development, technical correction, and product transformation. Every product needs to go through several strict quality inspection processes to ensure that the product has the best appearance and performance, delivering the most cost-effective product to every user and providing reliable product guarantee for customers.