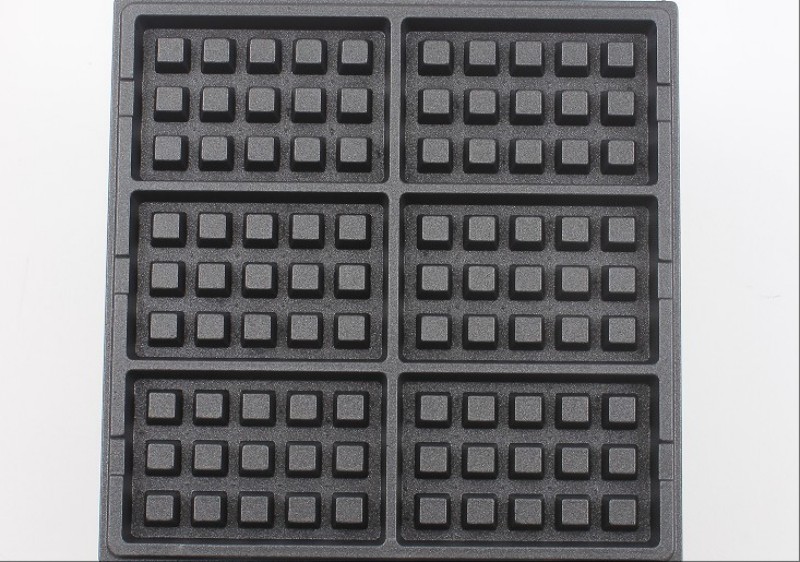

Six Grids Electric Waffle Maker

Category: Waffle Maker

-

+86-13929587046 WhatsApp

-

dfwuch67@gmail.com Email

Industrial Waffle Maker Machine has a large baking tray of 22.2×22.2cm, which is divided into six rectangular grids, each of which is 10×6.5cm in size, with an overall size of 310×450×280mm. The machine body is equipped with an independent power switch, temperature control knob and time setting knob. The entire shell is made of stainless steel. It is an electric industrial equipment designed for medium and high-capacity waffle production scenarios. It uses food-grade aluminum plate as the basic structure, and the baking tray surface is covered with a high-efficiency Teflon non-stick coating, which has excellent thermal conductivity and demolding performance.

Six Grids Electric Waffle Maker Parameter

| Model | MLP-136 |

| Name | Six Grids Electric Waffle Maker |

| Voltage/Frentcy | 220~240V/50~60Hz |

| Pwoer | 1.7KW |

| Dimension | 310*450*280mm |

| Packing Size | 47*35.5*32mm |

| Usage | Snacks Food Machine |

| Feature | High Productivity |

| Warranty | 1 Year |

| N.W/G.W | 8kg/10kg |

Six Grids Electric Waffle Maker Features

1. Efficient six-grid design to improve unit output and efficiency

The biggest highlight of Industrial Waffle Maker Machine is its high-efficiency design that can produce 6 rectangular waffles at a time. Compared with traditional four-grid, single-grid or double-grid waffle machines, this model can produce more products in a single-wheel operation, greatly shortening the overall meal delivery cycle and meeting the concentrated demand during peak hours. It is especially suitable for commercial places that require fast supply, such as breakfast fast food stores, school canteens, and convenience restaurants.

2. Teflon baking tray material, taking into account demoulding, heat conduction and cleanliness

The baking tray used by Industrial Waffle Maker Machine is a high-strength aluminum plate base, and the surface is covered with a high-temperature resistant, food-grade Teflon non-stick coating. This material has excellent demoulding performance. Even if multiple batches are baked at high temperatures continuously, it will not cause the batter to stick or carbonize residue, greatly reducing the downtime and maintenance time caused by the frequency of cleaning. Its heat-resistant temperature can reach above 250℃, ensuring stable operation in high temperature environments.

3. Safe electrical structure, more assured operation

Industrial Waffle Maker Machine has a triple safety structure design, which provides strong protection for electrical safety and temperature control protection during operation. First of all, Industrial Waffle Maker Machine has a built-in electrical component safety limiter. In the event of abnormal operation of the equipment, temperature out of control, or a dangerous signal during continuous use, the system will automatically cut off the power supply to prevent internal overheating, component damage or fire accidents, and protect the safety of personnel and property.

1. Fast food chains and food courts in shopping malls

In high-traffic places such as fast food chains or food courts in shopping malls, the production efficiency of the equipment directly determines the revenue capacity. The Industrial Waffle Maker Machine can quickly produce 6 waffles per round, and users can easily achieve continuous food delivery within 3 to 5 minutes, significantly increasing the number of people served per unit time. This is especially important for specific periods such as breakfast peaks, weekend gatherings, and temporary promotions.

2. Central kitchens and food factories: Standardized prefabricated waffle embryo mass production tool

For food processing plants or central kitchens, the Industrial Waffle Maker Machine is an ideal medium-sized production line auxiliary equipment. It can be used to make standardized frozen waffle embryos for cold chain transportation, vacuum packaging and other processes, and supply convenience stores, supermarkets, airline catering and other scenarios. The Industrial Waffle Maker Machine has precise temperature control and uniform output, which facilitates unified packaging and quality control of finished products.

3. Boutique coffee shops and creative dessert shops: a powerful tool for developing diversified menus

For boutique coffee shops that focus on visual desserts and creative beverage combinations, the Industrial Waffle Maker Machine provides a stable production base. The six-grid rectangular structure can be used to develop a variety of products with different ingredients, sauces, and stacking methods, such as chocolate filling, cheese wrapping, nut shreds embedded, etc., forming a customized, high-premium product portfolio to meet the psychological needs of young customers to "check in and take photos".

DINGFENG POPULAR PRODUCTS

Jiangmen Dingfeng Saving Kitchen Electric Co., Ltd. owns a modern production factory covering an area of over 10,000 square meters. Inside the factory, more than 80 well - trained employees perform their respective duties, forming a professional and efficient production team. Since its establishment, with exquisite technology and innovative ideas, the company has successfully produced more than 1000 different types of products. The rich variety of products fully demonstrates our strong production capacity and innovative vitality.

The company's main business is extensive, covering various kitchen electrical products. The product range is rich and diverse, including desktop luxury stoves cooker range, griddle, waffle baker, barbecue grills, deep fryers, panini grills, ice cream machine etc., fast food equipment, snack equipment, refrigeration, and other general commercial kitchen equipment. We have cooperated with more than 200 well-known brands around the world and have won a good reputation in the international market with our high-quality products and services, becoming a trusted partner for many customers. Our brand MARUPIN is widely well known by customers domestic and overseas.

Our company has invested heavily in introducing advanced equipment, equipped with world-class CNC punching, cutting, bending, and welding series processing equipment, and has strong technical strength to adapt to product development, technical correction, and product transformation. Every product needs to go through several strict quality inspection processes to ensure that the product has the best appearance and performance, delivering the most cost-effective product to every user and providing reliable product guarantee for customers.