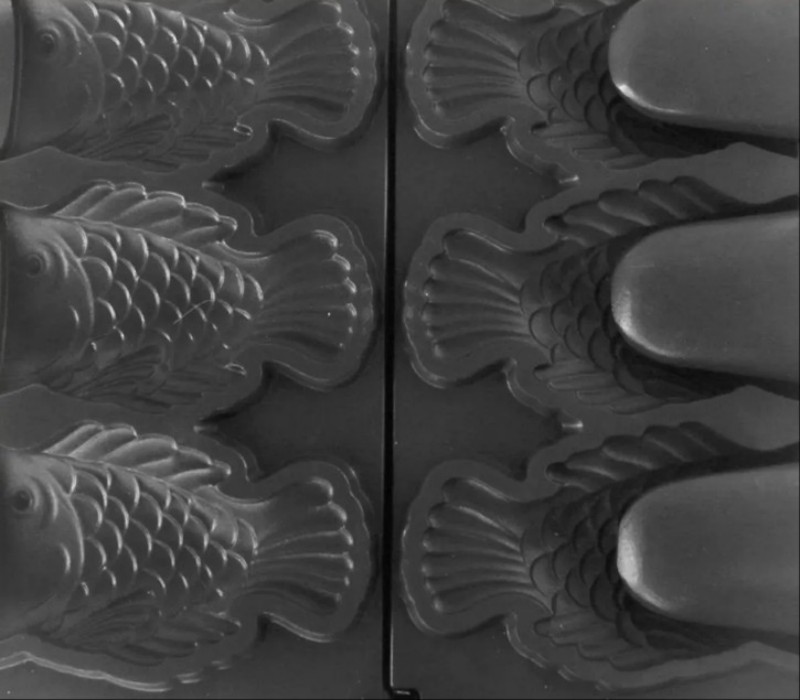

Three Fish Electirc Waffle Maker

Category: Waffle Maker

-

+86-13929587046 WhatsApp

-

dfwuch67@gmail.com Email

The Taiyaki Waffle Maker has a three-mold baking tray structure. The size of each mold is 7×15cm, the total heating area is 34×18.5cm, and the size of the whole machine is 440×425×285mm. It is equipped with non-slip rubber feet, and the bottom is designed with a sauce or residue collection box. The control area is equipped with a power switch, a timing knob and a temperature control knob, and is equipped with a red and green double light indicator function to display the heating and insulation status of the equipment. The anti-scalding handle is made of bakelite. It is an efficient and professional Taiyaki machine that integrates production capacity and safety.

Three Fish Electirc Waffle Maker Parameter

| Model | MLP-1103B |

| Name | Three Fish Electirc Snapper |

| Voltage/Frentcy | 220~240V/50~60Hz |

| Pwoer | 2KW |

| Dimension | 440*425*285mm |

| Packing Size | 500*450*300mm |

| Usage | Food Industry Equipment |

| Feature | High Productivity |

| Warranty | 1 Year |

| N.W/G.W | 18.3kg/20kg |

Three Fish Electirc Waffle Maker Features

Three-mold integrated structure design, efficient output, suitable for mass production

Taiyaki Waffle Maker has a three-mold baking tray structure, which can bake three complete Taiyaki at a time, greatly improving the efficiency of serving. During business peak hours, operators do not need to frequently wait for the mold to cool or change positions. They only need to pour the batter once after preheating to complete the baking of three products in a short time. Such production capacity performance is particularly suitable for sales scenarios with strict requirements on speed and efficiency, such as high-traffic dessert stores, night market snack stalls, and airport pop-up points. The baking tray adopts a standard mold size of 7×15cm per mold to ensure the uniform appearance of Taiyaki and the standardization of the finished product, which is convenient for subsequent packaging and pricing, and also convenient for the brand to develop product series.

Food-grade Teflon coating, non-stick and easy to clean, safe and hygienic

In the use of baking equipment, non-stick performance is directly related to the smoothness of operation and the aesthetics of product molding. The inner surface of the baking tray of Taiyaki Waffle Maker uses a food-grade Teflon coating, which has excellent anti-adhesion properties and high temperature resistance. Even if it is used repeatedly for a long time at 300℃, the coating will not peel off due to thermal expansion, ensuring that the ingredients are not too sticky or carbonized. This not only reduces the dependence on grease, but also makes it easier for users to clean the equipment. When cleaning, just wipe with a damp cloth to remove the residue, avoid using tools such as steel wool to cause equipment loss, extend the service life, greatly reduce maintenance costs, and improve overall operational efficiency.

Intelligent temperature control + timing function to ensure that each product is baked consistently

Taiyaki Waffle Maker uses a precise electronic temperature controller that can freely adjust the temperature within the range of 50℃300℃ to meet the heat treatment requirements of different batter concentrations and filling types. The high-sensitivity timing knob supports 05-minute timing settings. Operators can freely set the heating time according to factors such as batter foaming characteristics and filling moisture content to reduce human errors. With the status indicator light system, even novice operators can easily master the rhythm of use to ensure stable food quality and consistent taste. This dual guarantee of "equipment intelligence + human-friendly" brings more possibilities for large-scale commercial operations.

Safety detail design, safer operation and more durable structure

In actual commercial scenarios, the safety and stability of the equipment are particularly critical. Taiyaki Waffle Maker focused on the configuration of the protective structure at the beginning of its design. The handle is made of high-density bakelite. Even under high-temperature working conditions, the outer layer still maintains a low-temperature touch, effectively preventing the operator from being scalded; the bottom is equipped with a non-slip foot pad and an excess sauce collection box to effectively fix the device position and isolate stains; in addition, the internal circuit is equipped with an electrical component safety limiter, which can automatically cut off the power supply in case of abnormal temperature or voltage fluctuations, reducing the risk of equipment damage or safety accidents. The addition of these details reflects the equipment's comprehensive consideration of durability and safety in commercial high-frequency environments.

Applied to Singapore's "Kyodai Taiyaki" Airport Chain Dessert Station

"Kyodai Taiyaki" is a chain stall specializing in Japanese desserts at Singapore Changi Airport. Taiyaki Waffle Maker is widely deployed in its various stores. Thanks to its efficient three-mode design and precise temperature control system, Taiyaki Waffle Maker can continue to produce efficiently during busy periods at the airport to meet the fast-paced consumption needs of international passengers. At the same time, its non-stick coating facilitates quick cleaning during short downtime, providing a good working experience for store staff and improving service turnover speed.

Applied to the flagship store of the creative dessert brand "Mochi&Mame" in Seoul, South Korea

As a brand that focuses on Japanese-style desserts and modern innovative fillings, "Mochi&Mame" uses Taiyaki Waffle Maker to produce limited-edition Taiyaki products every day. The mold precision and appearance consistency of Taiyaki Waffle Maker meet the brand's high requirements for product aesthetics. The Teflon coating keeps the dough completely demolded while also ensuring food hygiene. It is an important hardware foundation for the realization of its creative fillings such as purple potato cheese and matcha egg yolk lava.

Applied to the fast food stalls around the campus of "Tokyo Bite" in Manila, Philippines

In the "Tokyo Bite" stalls around many university towns in the Philippines, Taiyaki Waffle Maker is used as the main product for the sales of thousands of Taiyaki every day. The equipment has a power of up to 2KW, can heat up quickly and maintain a stable heat output, so that students can quickly buy freshly baked and sold food in a short time after class or during class breaks, becoming a guarantee tool for the brand to exceed 100 orders per day. Merchants said that Taiyaki Waffle Maker is easy to operate, produces food quickly and has a low failure rate, which is one of the important reasons why they chose Taiyaki Waffle Maker.

DINGFENG POPULAR PRODUCTS

Jiangmen Dingfeng Saving Kitchen Electric Co., Ltd. owns a modern production factory covering an area of over 10,000 square meters. Inside the factory, more than 80 well - trained employees perform their respective duties, forming a professional and efficient production team. Since its establishment, with exquisite technology and innovative ideas, the company has successfully produced more than 1000 different types of products. The rich variety of products fully demonstrates our strong production capacity and innovative vitality.

The company's main business is extensive, covering various kitchen electrical products. The product range is rich and diverse, including desktop luxury stoves cooker range, griddle, waffle baker, barbecue grills, deep fryers, panini grills, ice cream machine etc., fast food equipment, snack equipment, refrigeration, and other general commercial kitchen equipment. We have cooperated with more than 200 well-known brands around the world and have won a good reputation in the international market with our high-quality products and services, becoming a trusted partner for many customers. Our brand MARUPIN is widely well known by customers domestic and overseas.

Our company has invested heavily in introducing advanced equipment, equipped with world-class CNC punching, cutting, bending, and welding series processing equipment, and has strong technical strength to adapt to product development, technical correction, and product transformation. Every product needs to go through several strict quality inspection processes to ensure that the product has the best appearance and performance, delivering the most cost-effective product to every user and providing reliable product guarantee for customers.