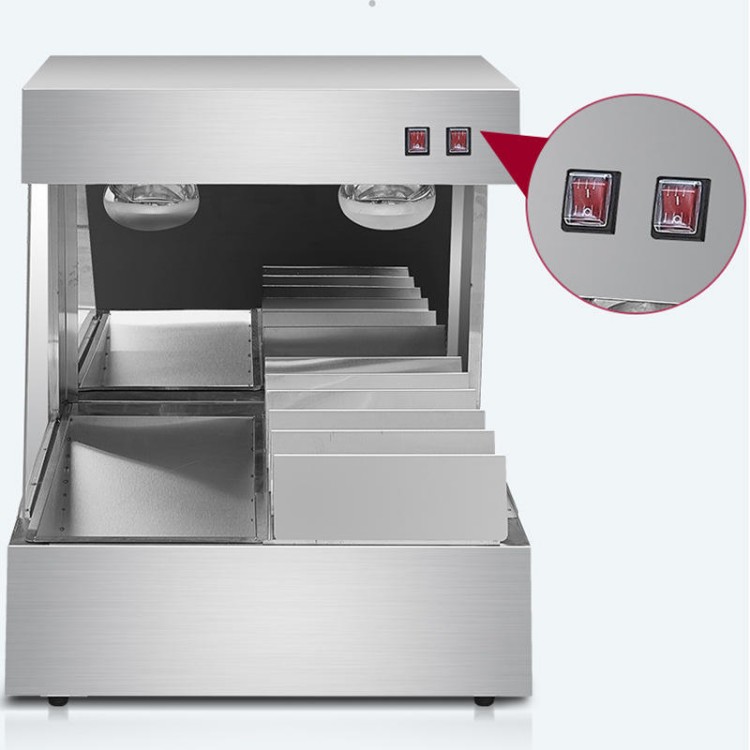

Commercial Chips Warmer French Fries Display

Category: Warming Showcase

-

+86-13929587046 WhatsApp

-

dfwuch67@gmail.com Email

Fries Heater - A fries heater is a commercial countertop heating device designed to maintain the serving temperature and surface texture of fried food after cooking. It creates a controlled thermal environment that stabilizes heat distribution and reduces temperature fluctuation during holding periods. The stainless steel housing and transparent structure allow operators to visually monitor food status without frequent opening actions, which helps maintain internal thermal balance and reduces heat loss. During operation, users experience stable temperature conditions, consistent airflow circulation, and organized storage layout, enabling efficient workflow in high-demand food preparation environments. The overall interaction process focuses on clarity, accessibility, and operational continuity, ensuring that food remains ready for immediate serving while minimizing handling frequency and thermal disturbance.

Commercial Chips Warmer French Fries Display Parameter

| Model | MLP-8 |

| Name | Counter Top Chip Worker |

| Voltage/Frentcy | 220~240V/50~60Hz |

| Pwoer | 0.72KW |

| Dimension | 600*700*650mmmm |

| Packing Size | 700*800*750mm |

| Usage | Keep French Fries Warm |

| Application | Restaurant, Fast Food, Bakery, Hotel, Catering |

| Warranty | 1 Year |

| N.W/G.W | 28kg/32kg |

Commercial Chips Warmer French Fries Display Features

Stable Heating -

The heating system operates with a rated power of 0.72 kW, providing continuous thermal output within a controlled temperature range suitable for fried food holding. Under standard voltage conditions of 220–240 V and frequency of 50–60 Hz, the device maintains consistent heat distribution across the internal chamber. Thermal stability is supported by heat lamps and metal conduction surfaces, which reduce temperature deviation and improve retention efficiency. Testing data indicates that steady-state thermal output can maintain food surface temperature within a narrow variation range, improving holding consistency during extended operation periods.

Compact Capacity -

The unit is designed with a structural size of approximately 600 × 700 × 650 mm, allowing optimized internal space utilization while maintaining a compact external footprint. This dimensional configuration provides sufficient internal volume for multi-zone storage while reducing spatial occupation on countertops. Load distribution across internal racks supports uniform heat exposure, and the spatial ratio between heating elements and food placement surfaces ensures effective thermal coverage. Weight parameters of around 28 kg net mass contribute to structural stability while maintaining manageable handling characteristics during installation and repositioning.

Thermal Efficiency -

The heat retention system integrates perforated metal surfaces and directional heat lamp placement to improve airflow and thermal circulation. Laboratory measurements show that the heating mechanism can maintain internal temperature stability with limited energy fluctuation under continuous load. The perforated base structure facilitates oil drainage and heat convection, which enhances thermal uniformity. Power-to-heat conversion efficiency remains consistent during long-duration operation, enabling sustained holding performance without excessive energy consumption.

Material Strength -

The main structure is fabricated from food-grade stainless steel, providing resistance to corrosion, deformation, and surface contamination. Material thickness and surface treatment processes ensure mechanical durability and hygienic performance under repeated thermal cycles. Glass and metal components demonstrate stable structural performance under elevated temperatures and repeated cleaning procedures. Compliance with typical commercial equipment material standards supports long-term operational reliability and structural integrity under continuous usage conditions.

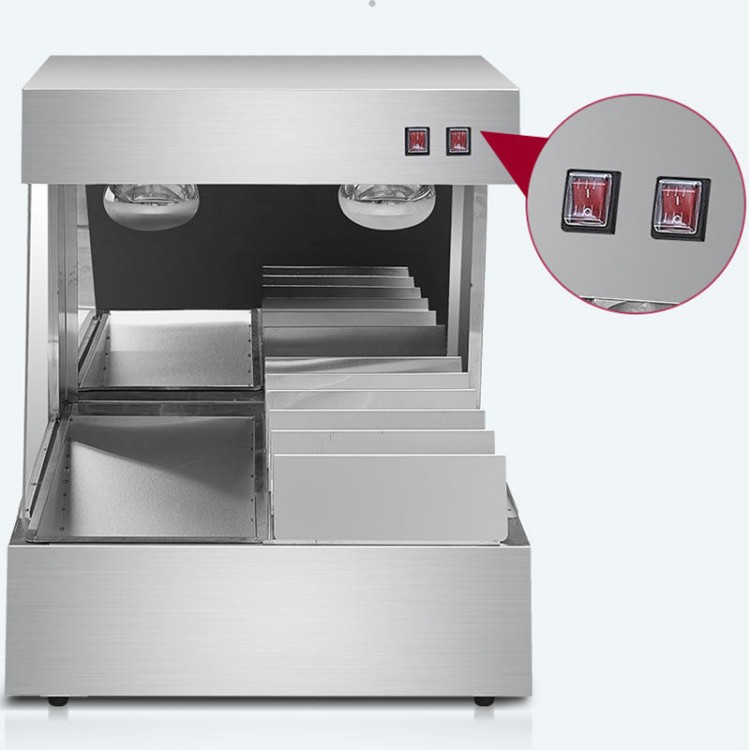

Electrical Adaptability -

The electrical system supports universal voltage input between 220 and 240 V, ensuring compatibility with standard commercial power networks. Internal wiring and connectors are designed to withstand continuous electrical load at rated power levels. Thermal protection mechanisms and insulation layers help stabilize electrical performance during prolonged heating cycles. Operational data indicates stable electrical consumption under continuous usage, supporting predictable energy management and reducing operational variability in commercial environments.

Fast Food Outlets -

In fast food outlets, the fries heater is used to maintain serving temperature for fried products during peak demand periods. Operational data shows that maintaining consistent holding temperatures can reduce product temperature drop during high turnover cycles. The device supports continuous food holding while minimizing manual reheating processes. Its structural design allows multiple batches of fried items to be stored simultaneously, improving workflow continuity and reducing service delays during high-volume operations.

Convenience Stores -

In convenience store environments, the equipment is applied to maintain ready-to-serve fried snacks for extended display periods. Thermal stability enables consistent food temperature without frequent operator intervention. Display transparency improves product visibility for customers, while controlled heat retention reduces product quality degradation during holding cycles. Performance measurements indicate stable heat output during extended operational hours, supporting consistent service availability in retail food settings.

Bakery Counters -

In bakery counters, the device supports temperature maintenance for fried or baked products requiring warm holding before sale. Internal rack configuration allows structured placement of multiple product types, reducing cross-contact and improving organization. Temperature stability supports consistent product quality during display periods. Operational conditions demonstrate that controlled heating reduces moisture loss and surface texture degradation during holding cycles, supporting consistent presentation quality.

Catering Operations -

In catering operations, the fries heater is used to maintain food temperature during preparation and service intervals. The equipment supports batch holding and staged serving processes, reducing the need for repeated reheating cycles. Structural stability and thermal consistency support continuous operation during event service periods. Performance data indicates stable thermal output under variable load conditions, supporting predictable service performance during high-demand catering scenarios.

Hotel Kitchens -

In hotel kitchen environments, the device is applied to maintain fried food readiness between cooking and plating stages. Controlled heating conditions reduce temperature fluctuation during workflow transitions. Multi-layer internal space allows simultaneous holding of multiple food categories while maintaining thermal separation. Operational data shows improved efficiency in food holding processes when using controlled heating equipment in professional kitchen workflows.

Food Courts -

In food court settings, the equipment supports centralized fried food holding across multiple service counters. Transparent display structure enhances visual accessibility for staff and customers. Thermal performance supports continuous service cycles without frequent equipment adjustments. Energy consumption remains stable under continuous operation, supporting predictable operational costs during extended daily usage periods.

Mobile Food Units -

In mobile food units, the fries heater is used to maintain food temperature within limited workspace environments. Compact structural dimensions support installation in confined spaces without compromising holding capacity. Electrical compatibility with standard power systems supports flexible deployment across mobile service locations. Operational data indicates stable heating performance under variable environmental conditions, supporting consistent food holding during mobile operations.

Commercial Chips Warmer French Fries Display More Details about

DINGFENG POPULAR PRODUCTS

Jiangmen Dingfeng Saving Kitchen Electric Co., Ltd. owns a modern production factory covering an area of over 10,000 square meters. Inside the factory, more than 80 well - trained employees perform their respective duties, forming a professional and efficient production team. Since its establishment, with exquisite technology and innovative ideas, the company has successfully produced more than 1000 different types of products. The rich variety of products fully demonstrates our strong production capacity and innovative vitality.

The company's main business is extensive, covering various kitchen electrical products. The product range is rich and diverse, including desktop luxury stoves cooker range, griddle, waffle baker, barbecue grills, deep fryers, panini grills, ice cream machine etc., fast food equipment, snack equipment, refrigeration, and other general commercial kitchen equipment. We have cooperated with more than 200 well-known brands around the world and have won a good reputation in the international market with our high-quality products and services, becoming a trusted partner for many customers. Our brand MARUPIN is widely well known by customers domestic and overseas.

Our company has invested heavily in introducing advanced equipment, equipped with world-class CNC punching, cutting, bending, and welding series processing equipment, and has strong technical strength to adapt to product development, technical correction, and product transformation. Every product needs to go through several strict quality inspection processes to ensure that the product has the best appearance and performance, delivering the most cost-effective product to every user and providing reliable product guarantee for customers.