Vertical French Fries Warmer Station

Category: Warming Showcase

-

+86-13929587046 WhatsApp

-

dfwuch67@gmail.com Email

A French Fry Warming Station is a dedicated commercial food-holding unit designed to keep freshly cooked fries at a stable serving condition after frying, while maintaining an organized and efficient workflow for food service staff. Based on the images, this unit integrates overhead heating, open rack holding, and enclosed storage into a single vertical structure that supports continuous operation during peak service periods. From the user experience perspective, it functions as a buffer between cooking and serving, reducing rush-time pressure while keeping fries ready for immediate plating.

The visual design shows a stainless steel body with an elevated heating hood and open-access fry racks, allowing staff to quickly load and retrieve fries without interrupting workflow. Warm white halogen lighting provides clear visibility of food status, helping operators visually assess freshness without opening doors or touching product. The vertical layout and caster-mounted base make the unit easy to position near fryers or service counters, improving movement efficiency in compact commercial kitchens. Overall, the experience emphasizes speed, visibility, hygiene control, and operational continuity rather than cooking or reheating functions.

Vertical French Fries Warmer Station Parameter

| Model | MLP-10 |

| Name | Vertical French Fry Workstation |

| Voltage/Frentcy | 220~240V/50~60Hz |

| Pwoer | 1KW |

| Dimension | 600*700*1500mm |

| Packing Size | 810*710*1410mm |

| Usage | Keep French Fries Warm |

| Feature | Restaurant, Fast Food, Bakery, Hotel, Catering |

| Warranty | 1 Year |

| N.W/G.W | 85kg/90kg |

Vertical French Fries Warmer Station Features

Dedicated Heating

Dedicated Heating - The unit operates with a rated power of 1 kilowatt, providing continuous thermal output suitable for holding fried foods at serving temperature. Based on common commercial warming standards, a 1 kilowatt halogen-based system can maintain internal holding temperatures within a stable range around 60 to 90 degrees Celsius, which is commonly required to prevent fries from cooling too quickly after frying. The overhead heat source concentrates warmth downward, reducing heat loss caused by ambient air exposure. This targeted heating structure minimizes temperature fluctuation during repeated loading and unloading, supporting consistent holding performance across high-volume service cycles without over-drying the food.

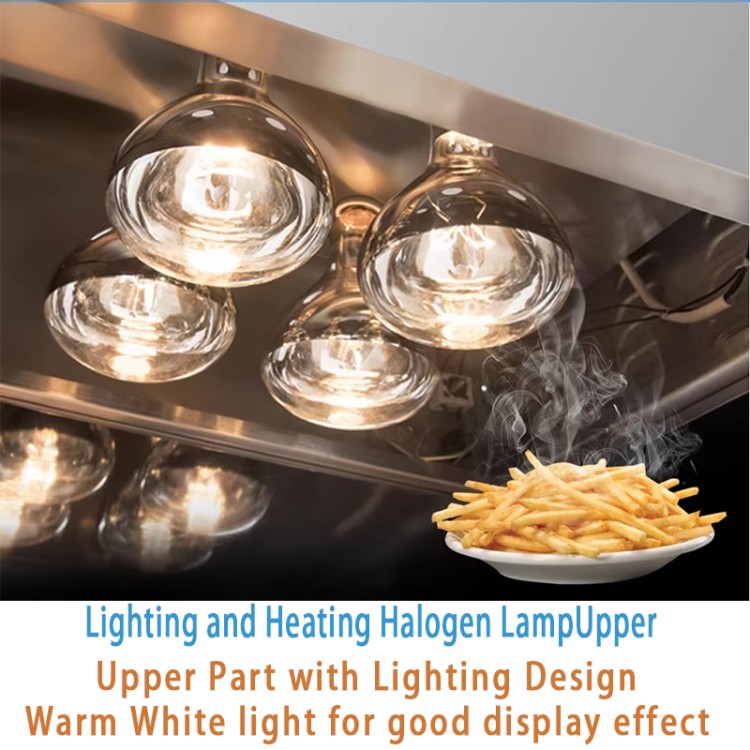

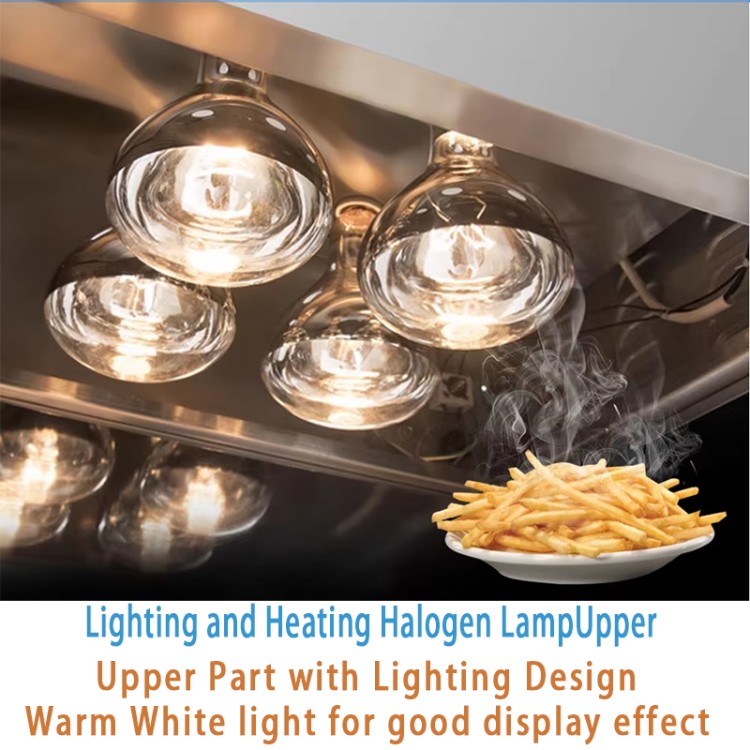

Halogen Lighting

Halogen Lighting - The warming station uses multiple halogen bulbs integrated into the upper heating hood, combining illumination and heat generation in one system. Halogen lamps typically operate at filament temperatures exceeding 2500 degrees Celsius, allowing them to emit both radiant heat and warm white light simultaneously. This dual-purpose design reduces the need for separate lighting fixtures while ensuring the holding area remains brightly visible. The warm white spectrum enhances food visibility by reducing color distortion, allowing staff to visually assess fry condition without additional inspection steps. The lighting remains stable during continuous operation, supporting long service hours.

Vertical Design

Vertical Design - With an overall dimension of approximately 600 by 700 by 1500 millimeters, the unit maximizes usable vertical space while minimizing floor footprint. This structure allows multiple fry racks and storage sections to be stacked vertically, increasing holding capacity without expanding horizontal workspace. In commercial environments where kitchen floor space is limited, a vertical footprint under 0.5 square meters allows placement near fryers, pass-through counters, or service lines. The height also positions heat sources above the food, improving airflow circulation and reducing direct contact with heating components, which supports safer daily operation.

Integrated Storage

Integrated Storage - The unit combines open warming racks with enclosed lower storage compartments, creating a unified workflow station. The lower cabinet provides space for trays, utensils, or packaging materials, reducing the need for additional storage furniture. Stainless steel storage panels typically exceed 0.8 millimeters in thickness, offering structural rigidity for repeated opening and closing during service. This integrated layout shortens movement distance for staff, reducing handling time per order. By centralizing warming and storage functions, the station supports higher throughput without increasing staff workload.

Stainless Structure

Stainless Structure - The entire frame and food-contact surfaces are constructed from stainless steel, a material widely used in commercial food equipment due to its corrosion resistance and hygiene performance. Stainless steel surfaces typically tolerate cleaning temperatures above 80 degrees Celsius and resist oxidation during long-term exposure to heat and moisture. The smooth surface finish reduces residue buildup and allows daily wipe-down cleaning using standard food-safe detergents. Structural stainless components also support a net unit weight of approximately 85 kilograms, indicating reinforced framing suitable for continuous commercial use.

Fast Food

Fast Food - In fast food restaurants, the warming station supports continuous fry holding during peak hours where order volume fluctuates rapidly. With a 1 kilowatt heating system, the unit can maintain stable holding conditions for multiple fry batches produced every few minutes. The open rack design allows staff to rotate fries quickly, ensuring first-in, first-out handling. This setup reduces order wait times during lunch and dinner rushes while maintaining product consistency. The vertical layout also allows placement directly beside fryers, minimizing transfer distance and reducing heat loss during movement.

Quick Service

Quick Service - In quick service environments with limited kitchen space, the vertical footprint of the unit allows operators to expand holding capacity without redesigning the kitchen layout. The 1500 millimeter height provides multiple holding levels within a narrow area, enabling efficient use of back-of-house zones. The integrated lighting helps staff visually monitor inventory levels from a distance, reducing unnecessary handling. This supports faster service speed and smoother workflow during high customer turnover periods.

Hotel Kitchens

Hotel Kitchens - In hotel food service operations, the warming station is used to hold fries for room service, buffet replenishment, or banquet service. The stainless steel construction withstands extended daily operation across multiple meal periods. The enclosed lower storage section allows staff to store service trays or backup containers near the holding area. With a rated power of 1 kilowatt, the unit can operate continuously without requiring frequent shutdowns, supporting long service windows common in hotel kitchens.

Catering Use

Catering Use - Catering environments require mobile and adaptable equipment that can be repositioned quickly. The caster wheel base allows the warming station to be moved between preparation areas and service zones without lifting. A unit weight around 85 kilograms ensures stability during movement while remaining manageable for staff. The vertical structure allows caterers to hold large quantities of fries in a compact footprint, which is especially useful in temporary or event-based kitchens where space is limited.

Bakery Service

Bakery Service - In bakeries offering hot savory items alongside baked goods, the warming station provides a dedicated area for fried or hot side items without interfering with baking equipment. The halogen lighting enhances product visibility for front-of-house presentation while maintaining warmth. The open rack configuration allows quick access during busy morning or afternoon service periods. Stainless steel surfaces support frequent cleaning to prevent cross-contact between food types.

Food Courts

Food Courts - In food court operations, the warming station helps vendors manage high order volume within constrained booth layouts. The vertical design allows placement behind counters without blocking customer-facing space. The overhead heating system reduces temperature drop caused by frequent customer orders. The integrated storage section helps vendors keep packaging materials organized within the same footprint, improving service efficiency and reducing clutter.

Convenience Stores

Convenience Stores - In convenience store food service areas, the warming station supports ready-to-serve fried snacks during extended operating hours. The stable heating output ensures fries remain warm without continuous monitoring. The halogen lighting draws visual attention to the food, improving perceived freshness for customers. With durable stainless steel construction, the unit withstands daily use in environments where staffing levels may be limited, reducing maintenance demands while maintaining consistent holding performance.

Vertical French Fries Warmer Station More Details about

DINGFENG POPULAR PRODUCTS

Jiangmen Dingfeng Saving Kitchen Electric Co., Ltd. owns a modern production factory covering an area of over 10,000 square meters. Inside the factory, more than 80 well - trained employees perform their respective duties, forming a professional and efficient production team. Since its establishment, with exquisite technology and innovative ideas, the company has successfully produced more than 1000 different types of products. The rich variety of products fully demonstrates our strong production capacity and innovative vitality.

The company's main business is extensive, covering various kitchen electrical products. The product range is rich and diverse, including desktop luxury stoves cooker range, griddle, waffle baker, barbecue grills, deep fryers, panini grills, ice cream machine etc., fast food equipment, snack equipment, refrigeration, and other general commercial kitchen equipment. We have cooperated with more than 200 well-known brands around the world and have won a good reputation in the international market with our high-quality products and services, becoming a trusted partner for many customers. Our brand MARUPIN is widely well known by customers domestic and overseas.

Our company has invested heavily in introducing advanced equipment, equipped with world-class CNC punching, cutting, bending, and welding series processing equipment, and has strong technical strength to adapt to product development, technical correction, and product transformation. Every product needs to go through several strict quality inspection processes to ensure that the product has the best appearance and performance, delivering the most cost-effective product to every user and providing reliable product guarantee for customers.